Product Description

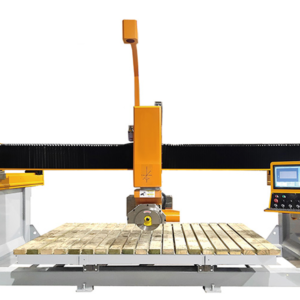

The Pneumatic Tool Change Machining Center is a high-performance CNC machine designed for automatic and precise processing of stone materials such as marble, granite, quartz, sandstone, and ceramic tiles. Engineered with a robust pneumatic tool change system, it offers flexible and efficient switching between multiple tools, enhancing productivity and accuracy in complex operations.

Ideal for fabricating countertops, under-table basins, edge polishing, grooving, engraving, and more, this machine is especially suitable for stone processing factories that require continuous, automated, and high-precision production. It supports CAD design import and offers template-based processing for common shapes like circles, ellipses, and squares, ensuring easy setup and exceptional results.

Key Features

-

Pneumatic tool change system allows fast and stable multi-tool operations without manual intervention.

-

High spindle speed (18,000 rpm) ensures smooth and detailed cutting, polishing, and engraving.

-

Compatible with CAD drawings, supporting quick import of customized patterns for efficient workflow.

-

3-axis linear guide rails (X, Y, Z) provide high positioning accuracy and strong structural stability.

-

Touchscreen interface for user-friendly operation and programming.

-

Template-based processing simplifies standard shapes like circles, polygons, squares, etc.

-

Supports height measurement device (optional) for consistent depth cutting and polishing.

-

Low-maintenance and energy-efficient design, suitable for long working hours in industrial settings.

Technical Parameters

| Parameter | Unit | Value |

|---|---|---|

| Max. Cutting Size | mm | 2900 × 1000 |

| Feed Height | mm | 100 |

| Max. Running Speed (X/Y) | mm/min | 20000 |

| Max. Running Speed (Z) | mm/min | 3000 |

| Repeat Positioning Accuracy | mm | 0.01 |

| Control System | / | Industrial CNC |

| Workpiece Fixed Way | / | Water suction |

| Spindle Speed | r/min | 18000 |

| Cutter Diameter | mm | φ10 |

| Cooling Method | / | Water cooling |

| Total Power | kW | 9 |

| Voltage | V | 380 |

| Machine Dimension | mm | 4000 × 2000 |

| Gross Weight | kg | Approx. 1800 |

| Spindle Motor Power | kW | 7.5 |

❓Frequently Asked Questions (FAQs)

Q1: What materials can this CNC machine process?

A1: It is suitable for marble, granite, quartz stone, sandstone, ceramic tiles, and other composite stones.

Q2: Can it perform multiple tasks like cutting and polishing?

A2: Yes. It supports various stone processing operations including cutting, edge grinding, basin hole carving, polishing, and grooving.

Q3: How is the tool changed automatically?

A3: The machine uses a pneumatic tool change system that quickly swaps tools during operation without stopping the workflow.

Q4: Does it support importing CAD files?

A4: Yes, CAD files can be imported for fast processing of custom shapes and patterns.

Q5: How accurate is the machine?

A5: It offers a repeat positioning accuracy of 0.01mm, suitable for high-precision applications.