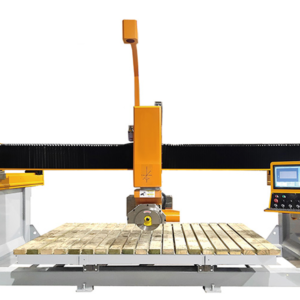

Product Description

The AC 5 Axis CNC Waterjet Cutting Machine redefines precision cutting by combining robust mechanics with smart 5-axis control. Powered by a high-pressure abrasive waterjet system, this machine easily handles everything from complex beveled cuts in stone to spiral contours in metal. Whether you’re producing custom countertops, industrial components, or architectural panels, the waterjet offers a cold-cutting process that leaves zero thermal damage and unmatched detail resolution.

From straight cuts to compound curves, from flat surfaces to 3D angles, this waterjet is your all-in-one solution. With its AC axis bevel head, industrial CNC control, and eco-conscious design, sets a new standard in automated precision cutting.

Key Features

- True AC 5-Axis Bevel Cutting

Supports ±65° tilt angles for multi-directional, compound bevel cutting — ideal for decorative miters, chamfers, and 3D profiles. - High-Precision Control System

Achieves ±0.05 mm positioning accuracy and ±0.02 mm repeatability, ensuring flawless results for detailed cuts. - Heavy-Duty Gantry Structure

Guarantees long-term cutting stability and vibration-free operation, even under heavy workloads. - Dual-Pressure Pump System

Adjustable water pressure for cutting materials of varying hardness and thickness. - Advanced CAD/CAM Software

Simplifies workflow with powerful nesting, toolpath generation, and DXF/NC file compatibility. - Eco-Friendly Cutting

Cold cutting process produces no thermal distortion, smoke, or hazardous fumes — safe and sustainable. - Smart 3D Cutting with Real-Time Control

Dynamic angle correction and curve processing via computer control.

Technical Parameters

| Parameter | Unit | Value |

|---|---|---|

| Cutting Area | mm | 3600 × 1800 |

| Max Workpiece Size | mm | 4100 × 2100 |

| Maximum Cutting Speed | m/min | 8 |

| X/Y Rapid Travel Speed | m/min | 10 |

| Z-Axis Travel Speed | m/min | 3 |

| A/C Axis Rotation Speed | °/sec | 120 |

| Positioning Accuracy | mm / 300 mm | ±0.05 |

| Repeatability Accuracy | mm | ±0.02 |

| Working Pressure | MPa | 280–360 (Max 450) |

| Water Flow Rate | L/min | 3.7 |

| Cooling System | — | Air-cooled oil system |

| Power Requirement | kW / Voltage | 37 kW / 220–415V |

| Control System | — | Industrial CNC |

Applications & Material Capability

-

Stone: Granite, marble, quartzite, sintered stone

-

Metals: Steel, aluminum, copper, titanium

-

Glass: Architectural, automotive, laminated glass

-

Ceramics: Tiles, panels, sanitary ware

-

Other: Rubber, plastics, composites, carbon fiber

❓Frequently Asked Questions (FAQs)

Q1: What materials can this waterjet cut?

A: Granite, marble, quartz, metal (steel, aluminum), ceramics, glass, composites — all without heat damage.

Q2: Can the machine cut beveled or angled edges?

A: Yes! The AC 5-axis head supports ±65° compound angles — perfect for miters and 3D profiles.

Q3: Is the software easy to use?

A: Yes. The CAD/CAM software is user-friendly and supports DXF, NC, nesting, and toolpath generation.

Q4: What is the machine’s precision level?

A: Positioning accuracy is ±0.05 mm, and repeatability is ±0.02 mm — suitable for fine-detail work.

Q5: Do you provide installation and training?

A: Yes, we provide remote setup guidance, video training, and full documentation for global customers.