Product Description

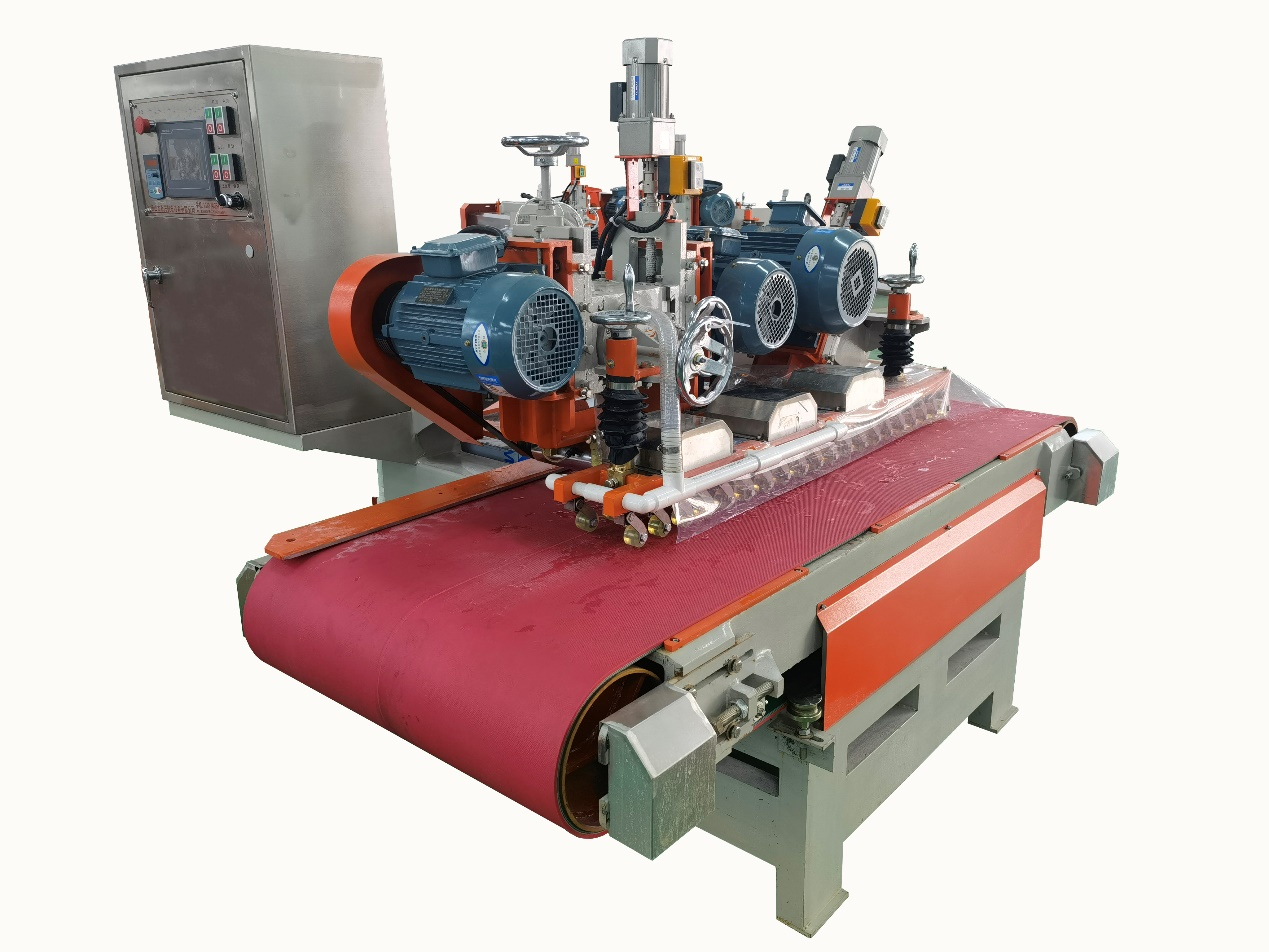

The 2400 CNC Triple-Blade Cutting Machine is purpose-built for high-efficiency, high-precision cutting of sintered stone, quartz, marble, ceramic tiles, and other engineered or natural stone materials. Designed to handle extra-large format slabs, it supports unlimited cutting length and a maximum width of 2400mm (double 1200mm), making it an ideal solution for modern slab processing plants.

This all-in-one cutting solution integrates three specialized blades — edge trimming, pre-cutting, and final cutting — to ensure clean, burr-free cuts with no chipping or size deviation. Its automatic water-cooling system, CNC-guided precision, and high-speed cutting capability (up to 6 meters/minute) enable continuous operation with reduced labor and production costs.

Whether you’re processing porcelain slabs, quartz countertops, or large marble sheets, the 2400 model guarantees superior cutting quality, operational stability, and production efficiency.

Key Features

- Triple Blade Structure for Seamless Cutting: One-pass operation with edge trimming, pre-cutting, and final cutting ensures chip-free, burr-free results with perfect edge finishing.

- Versatile Material Compatibility: Designed for processing a wide range of materials including sintered stone, quartz, ceramic tiles, marble, and large-format porcelain slabs.

- High-Speed Batch Production: Cutting speed up to 6 meters/min, equivalent to the productivity of five traditional hand-operated machines.

- Wide and Unlimited Cutting Dimensions: Handles slabs up to 2400mm in width (double-sided 1200mm) and unlimited length, ideal for oversized tile and stone panel manufacturing.

- Smart CNC Control System: Featuring precision ball screws, linear guides, and touchscreen control for easy operation and consistent results with ±0.1mm tolerance.

- Automatic Water Cooling: Integrated over-slab water flow cooling system protects the blades, reduces friction, and supports long-term continuous cutting.

- Fast Blade Replacement & Maintenance: Each of the three blades is equipped with an automatic lifting mechanism for faster blade changes and reduced downtime.

- Robust Build with Optimized Transmission: Features precision gear motor with frequency conversion, enhancing torque control and machine lifespan.

.

Technical Parameters

| Parameter | Unit | Value |

|---|---|---|

| Machine Dimensions | mm | 2500 x 2400 x 2000 (Model 1800 / Model 1200) |

| Conveyor Belt Width | mm | 1300 |

| Cutting Width Range | mm | 20 – 2400 (double-sided 1200mm each) |

| Front Blade Motor Power | kW | 3 |

| Front Blade Spec | mm | φ130 x φ20 x 2.5 Resin Wheel |

| Middle Blade Motor Power | kW | 4 |

| Middle Blade Spec | mm | φ130 / φ150 |

| Rear Blade Motor Power | kW | 5.5 |

| Rear Blade Spec | mm | φ130 / φ150 |

| Material Pusher Mechanism | — | Precision Lead Screw + Stepper Motor |

| Control System | — | Swing Electric Box + Touchscreen |

| Transmission Type | — | Gear Drive + Variable Frequency Motor |

| Transmission Power | kW | 1.1 |

| Processing Speed | m/min | 1 – 6 |

| Output Table (Optional) | mm | 2000 x 1000 x 800 |

❓Frequently Asked Questions (FAQ)

Q1: What materials can this machine cut?

A1: The machine is compatible with sintered stone, quartz stone, marble, ceramic tiles, and large-format porcelain slabs.

Q2: What is the maximum cutting size?

A2: The machine can process slab widths up to 2400mm (double-sided 1200mm) with unlimited length, making it ideal for cutting oversized panels.

Q3: Is this machine suitable for batch production?

A3: Yes, it is designed for high-efficiency batch production with a cutting speed of up to 6 meters per minute, significantly improving productivity.

Q4: How accurate is the cutting process?

A4: The CNC system ensures precision cutting with an accuracy of ±0.1mm, supported by high-quality ball screws and linear guides.

Q5: What kind of maintenance does the machine require?

A5: Routine maintenance includes checking the blade wear, cleaning the water cooling system, and ensuring smooth operation of the guide rails and control systems.

Q6: Is the machine easy to operate?

A6: Yes, it comes with a user-friendly touchscreen interface and a smart CNC system, making it easy to control and monitor even for new operators.

Q7: How does the water cooling system work?

A7: An automatic over-slab water cooling system flows continuously to cool the blades during cutting, reducing wear and supporting long-term operation.