Machines CNC pour meubles de salle de bain, découpes d’évier et panneaux muraux

Que peut-on faire avec les machines CNC de Midecnc ?

Les machines CNC de Midecnc permettent aux fabricants de salles de bains de gérer des conceptions complexes, des matériaux variés et des finitions avec efficacité et précision. Qu’il s’agisse de découpes précises pour les éviers, d’arêtes en onglet sans joint pour les plans de travail ou de gravures décoratives sur panneaux en céramique, nos solutions simplifient la production et renforcent la flexibilité de conception.

Applications CNC typiques pour la salle de bain

Fabrication de plans vasques

Découpe en onglet, finition des bords et polissage sans joint pour plans de travail sur mesure

Découpes pour éviers et robinets

Perçage automatique pour éviers, robinets et trous de drainage

Usinage de panneaux muraux

Découpe de grandes dalles et assemblage sans joint pour murs de salle de bains

Gravure artistique de surface

Découpe en onglet, finition des bords et polissage sans joint pour plans de travail sur mesure

Fraisage de rainures antidérapantes

Fraisage de rainures peu profondes pour améliorer la sécurité et l'adhérence dans la douche

Fraisage de rainures pour fixations

Fraisage de cavités pour fixations dissimulées (par ex. armoires, supports)

Capacités d'usinage typiques

Découpes pour évier

Perçage automatique de trous d’évier et découpe du contour intérieur

Plans de toilette

Découpe en onglet précise pour plans de toilette sans joint

Panneaux muraux

Découpe de grandes dalles pour murs de douche ou zones humides

Détails gravés

Gravure de motifs sur pierre ou porcelaine avec un rendu type laser

Rainures antidérapantes

Découpe de tranchées peu profondes à la base de la douche pour éviter de glisser

Perçage de trous

Perçage automatique de trous ronds/carrés

Galerie d’applications

Découvrez les applications concrètes des machines Midecnc dans l'industrie de la salle de bain — de la fabrication de plans de travail en pierre à la gravure artistique. Ces études de cas montrent comment nos solutions CNC apportent précision, efficacité et flexibilité créative à chaque étape de traitement.

Fabrication de plans vasques en pierre grand format

Un flux de production complet depuis le chargement des plaques, la découpe des éviers jusqu’au traitement des bords en biseau à 45°. Cette solution est idéale pour les plans vasques haut de gamme sur mesure, alliant robustesse, précision et jonctions sans faille.

- Prend en charge les coupes droites et en biseau à 45° pour un assemblage de comptoir sans joint.

- Perçage à grande vitesse et découpe de contour pour éviers ronds ou de formes personnalisées.

- Le polissage des bords lisses améliore la qualité visuelle et tactile.

Découpe intégrée de panneaux muraux

Découpe de grandes dalles en porcelaine aux dimensions des murs de douche avec un minimum de perte de matériau

Perçage automatisé pour éviers et robinets

Perçage automatisé des trous d’évier, des ouvertures pour robinets et des fentes d’installation.

Gravure artistique de surface

Gravure personnalisée sur carreaux en céramique pour panneaux muraux décoratifs.

Fraisage de rainures antidérapantes pour sol de douche

Des rainures peu profondes sont fraisées avec précision sur des surfaces en carrelage ou en pierre pour améliorer l'adhérence dans les zones humides

Principaux avantages techniques

Les solutions CNC de Midecnc pour l'industrie de la salle de bains offrent une automatisation, une précision et une compatibilité matérielle de premier plan. Que vous soyez un fabricant sur mesure ou un producteur en série, nos machines sont conçues pour réduire la main-d'œuvre, minimiser les déchets et améliorer la productivité.

Avantage 1 : Automatisation du flux de travail intégré

Du chargement de la dalle au polissage final des bords, une seule machine gère l'ensemble du processus avec une intervention humaine minimale.Avantage 2 : Précision de ±0,02 mm pour un assemblage sans joint

Les systèmes servo de haute précision assurent un assemblage parfait — idéal pour les joints en onglet à 45° et les assemblages multi-panneaux.Avantage 3 : Flexibilité de découpe multi-matériaux

Compatible avec la pierre frittée, la céramique, la porcelaine et le verre, permettant un développement de produits plus large pour les designs de salles de bains modernes.Imbrication intelligente et réduction des déchets

La planification optimisée des trajets et le logiciel d’imbrication réduisent les déchets de matériaux et augmentent l’efficacité de découpe.

Machines recommandées

Choisissez la solution CNC idéale adaptée à la fabrication de produits de salle de bain. De la fabrication de plans de toilette à la gravure de précision, Midecnc propose des modèles fiables pour toutes les tailles d’exploitation.

Machine CNC pour découpe d’évier

Perçage et fraisage automatisés pour les trous d’évier, de robinet et d’installation.

- Cycles rapides adaptés à la production de masse.

- Compatibilité avec formes modèles et formes libres

- Disposition compacte, facile à intégrer

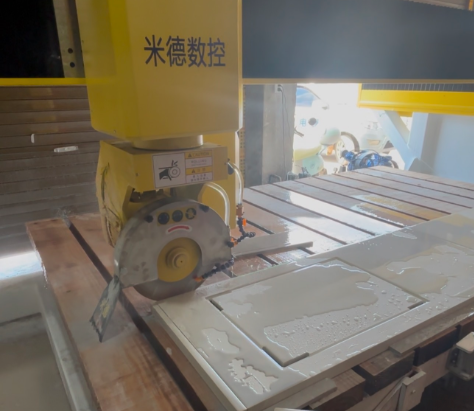

Scie pont CNC 4 axes

Une scie à pont CNC puissante et facile à utiliser, conçue pour la découpe de plans de travail et de panneaux de salle de bains. La configuration à 4 axes permet des coupes en biais, le perçage de trous et une manipulation flexible des dalles, idéale pour les professionnels de la pierre.

- Flexibilité de coupe à 4 axes : permet des coupes droites, en biais et circulaires avec une grande précision

- Perçage intégré : Réalise les découpes de trous pour robinet, évacuation ou évier en un seul processus

- Châssis robuste et commande facile : Conçu pour la stabilité et une utilisation intuitive

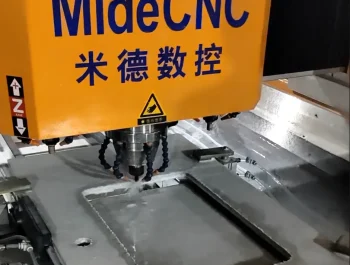

Scie à pont CNC 5 axes (4020AC)

Une machine tout-en-un puissante, idéale pour la découpe, le chanfreinage et le perçage de grandes dalles.

- Contrôle 5 axes pour des coupes en biseau et en angle avancées

- Changement d’outil automatique pour un traitement polyvalent

- Convient pour la pierre frittée, le quartz et la céramique

Plébiscité par les fabricants de meubles de salle de bain du monde entier

La scie à pont de Midecnc a réduit de 40 % notre temps de découpe pour les éviers — nous traitons plus de commandes avec moins de main-d'œuvre.

— Le Minh Stoneworks, Vietnam

Questions fréquemment posées

Quels matériaux en pierre sont compatibles avec les machines Midecnc ?

Nos machines prennent en charge le granit, le marbre, la pierre artificielle, le quartz et la céramique.

Votre machine CNC peut-elle découper à la fois les trous pour l’évier et pour le robinet ?

Oui. Les découpes pour évier et les perçages pour robinet peuvent être programmés en une seule configuration.

La découpe de plateaux d’égouttage inclinés est-elle prise en charge ?

Absolument, en utilisant notre centre d’usinage ou scie à pont avec fonction de chanfreinage.

Quelle est la précision moyenne pour les découpes des trous d’évier ?

Une précision de ±0,1 mm peut être atteinte avec un réglage approprié des outils.

Combien de temps faut-il pour usiner un plan de travail typique ?

Cela prend entre 10 et 30 minutes selon le matériau et la complexité du design.

Vos machines sont-elles compatibles avec les dessins CAO ?

Oui. Les formats standards tels que DXF ou DWG sont pris en charge.

Puis-je intégrer le polissage dans le même processus ?

Oui. Notre centre d’usinage prend en charge l’usinage et le polissage en un seul cycle.

Proposez-vous une installation et une formation pour les nouveaux utilisateurs ?

Oui. Nous fournissons un support à distance et sur site dans le monde entier.