CNC Glossary: 20 Terms Every Stone Fabricator Should Know

Essential terminology for mastering granite, marble, and sintered stone fabrication with CNC technology

Introduction

In the fast-evolving world of stone fabrication, CNC machines have become essential for producing precise, efficient, and creative designs. Whether you’re cutting marble, granite, quartz, or sintered stone, mastering the common terminology helps teams communicate, reduces errors, and unlocks the full potential of CNC bridge saws and stone cutting machines.

This glossary lists 20 essential CNC terms every stone fabricator should know — short, practical definitions you can use on the shop floor or when talking to clients.

CNC Terms Every Stone Fabricator Should Know

CNC (Computer Numerical Control)

Automated control of machine tools by a computer — converts digital designs into precise cutting movements used in granite, marble and sintered stone fabrication.

Axis (X, Y, Z, A, C)

Directions a CNC machine moves. Stone machines may be 3, 4, 4+1 or 5 axis — more axes = more complex cuts (e.g., bevels, miters, 3D forms).

G-Code

The numerical control programming language that instructs the CNC how to move, pause, change speed, and perform operations.

CAM (Computer-Aided Manufacturing)

Software that converts CAD models into toolpaths for the CNC — it plans the cut sequence, depths, and feeds for stone cutting jobs.

CAD (Computer-Aided Design)

Drawing and modeling tools used to create digital blueprints of countertops, sinks, and custom stone elements before manufacturing.

Bridge Saw

A stone cutting machine with a bridge structure and diamond blade specifically for cutting slabs — primary workhorse for countertop shops.

Spindle

The rotating motor that drives the cutting tool or blade — spindle speed (RPM) affects finish and cutting performance.

Toolpath

The programmed route the cutting tool follows across the slab — optimization reduces cycle time and improves accuracy.

Feed Rate

Speed at which the cutting tool travels through the material — must be balanced with RPM for a clean cut and long blade life.

RPM (Revolutions Per Minute)

How fast the spindle or blade rotates. Higher RPM can improve surface finish but must match feed and blade type.

Interpolation

The CNC method of moving smoothly between points — essential for accurate curves and multi-axis motion (linear and circular interpolation).

Kerf

The width of material removed by the blade or tool. Kerf affects final dimensions — always account for it in nesting and templates.

Coolant / Water Jet

Water or coolant that reduces heat, removes dust, and prolongs blade life when cutting hard stone and sintered slabs.

Fixture / Clamping

Methods and devices used to secure slabs during cutting — proper fixturing prevents vibration and ensures dimensional accuracy.

Origin / Zero Point

The reference point from which all cuts are measured — typically set at a corner or specific datum on the slab.

Nest / Nesting

Arranging multiple parts on a slab to minimize scrap. Smart nesting saves material and reduces production time.

Overtravel

Extra movement allowed beyond programmed path as a safety margin; must be controlled to avoid collisions or waste.

Backlash

Mechanical slack or lost motion in the drive system when changing direction — compensations in control or maintenance reduce its effect.

Pocketing

A machining operation that removes material within a defined area (e.g., sink cutouts), often executed with multiple passes.

Chamfer / Bevel

Angled edge finishes used in countertops and decorative elements; done by tilting or rotating the tool on multi-axis machines.

Why This Glossary Matters for Stone Fabricators

Understanding these CNC terms helps fabricators:

- Communicate clearly with technicians and clients

- Operate CNC bridge saws and 5 axis machines more efficiently

- Reduce mistakes and material waste (better nesting, correct kerf compensation)

- Expand creative possibilities with advanced machining techniques

Conclusion

CNC machines are revolutionizing marble, granite, quartz and sintered stone fabrication. By mastering these 20 key CNC terms, fabricators can elevate shop performance and get the most out of advanced machines such as the Midecnc 4+1 Axis and Midecnc 5 Axis CNC Bridge Saws.

Ready to Transform Your Stone Fabrication Process?

Discover how Midecnc bridge saws (4 Axis, 4+1 Axis, 5 Axis) can improve precision, throughput and profitability.

Contact Midecnc on WhatsAppRecommended Machines

For interior decoration professionals, Midecnc offers CNC machines that deliver precision, efficiency, and creative flexibility. Whether you’re working with sintered stone, ceramic panels, or composite materials, our bridge saws and engraving systems are optimized for both artistic detailing and structural fabrication.

5 Axis CNC Bridge Saw

Designed for top-tier interior and architectural applications, the 5-Axis CNC Bridge Saw enables ultra-precise mitre cuts, curve shaping, sink cutouts, and even sculpted reliefs—all in one intelligent workflow. Built for sintered stone, marble, quartz, and ceramic panels, it delivers unmatched efficiency and versatility for designers and fabricators.

- Photo Taking & Suction Cup System: Advanced alignment and stone stabilization system enhances safety and accuracy.

- True 5-Axis Cutting: Offers full XYZ movement with spindle rotation and tilt for advanced 3D profiling, edge shaping, and bevel cuts (up to 45°).

- Handles Complex Shapes: Ideal for cutting triangles, ellipses, diamonds, circles, countertops, tables, and more.

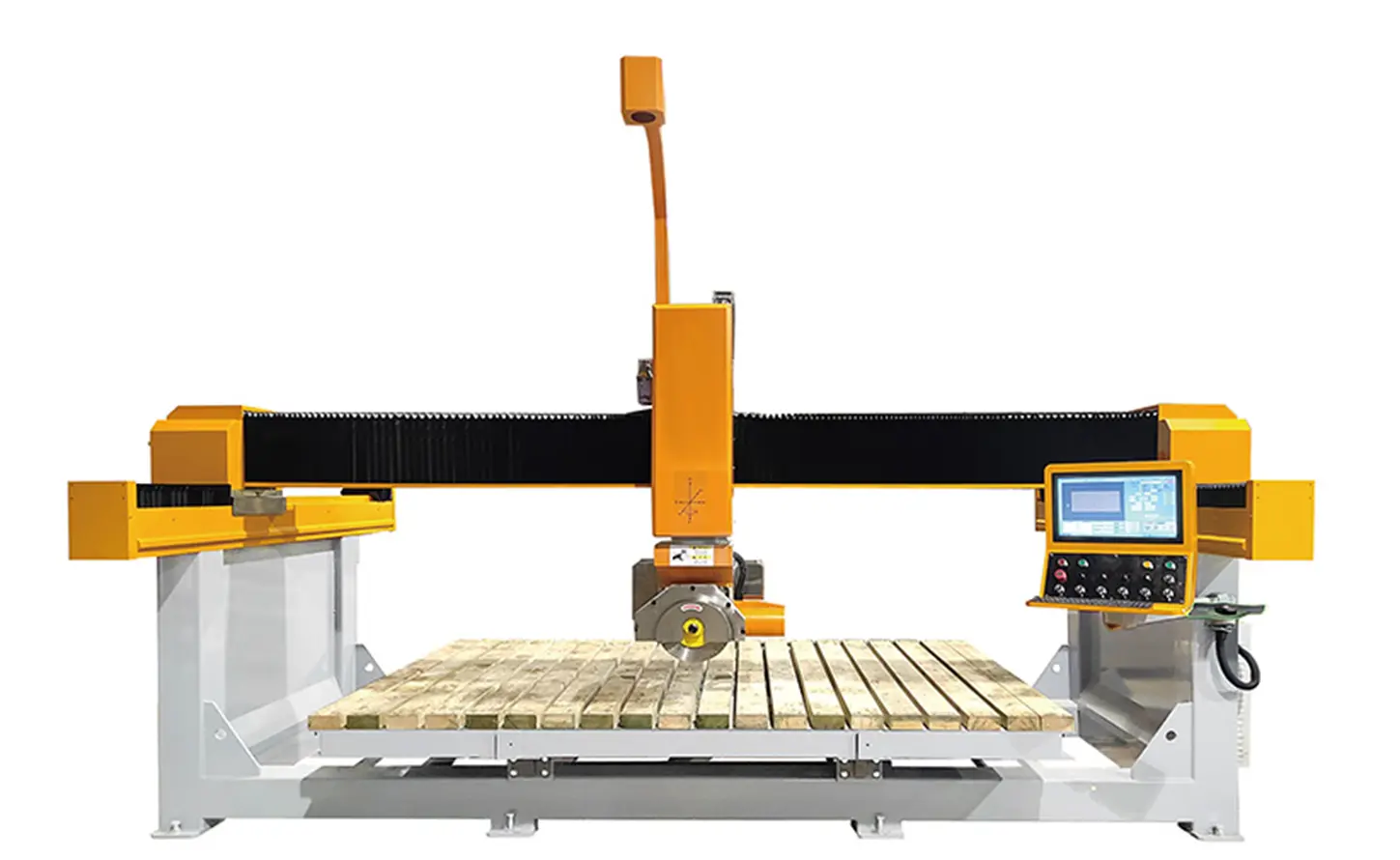

4+1 Axis CNC Bridge Saw

An ideal choice for projects requiring mitre cuts, linear polishing, and embedded slotting. Reliable, fast, and easy to use for everyday interior cutting tasks.

- ±90° blade rotation with 0–90° tilt

- Perfect for cabinet grooves and lighting slot creation

- Heavy-duty frame & easy control: Built for stability and intuitive operation

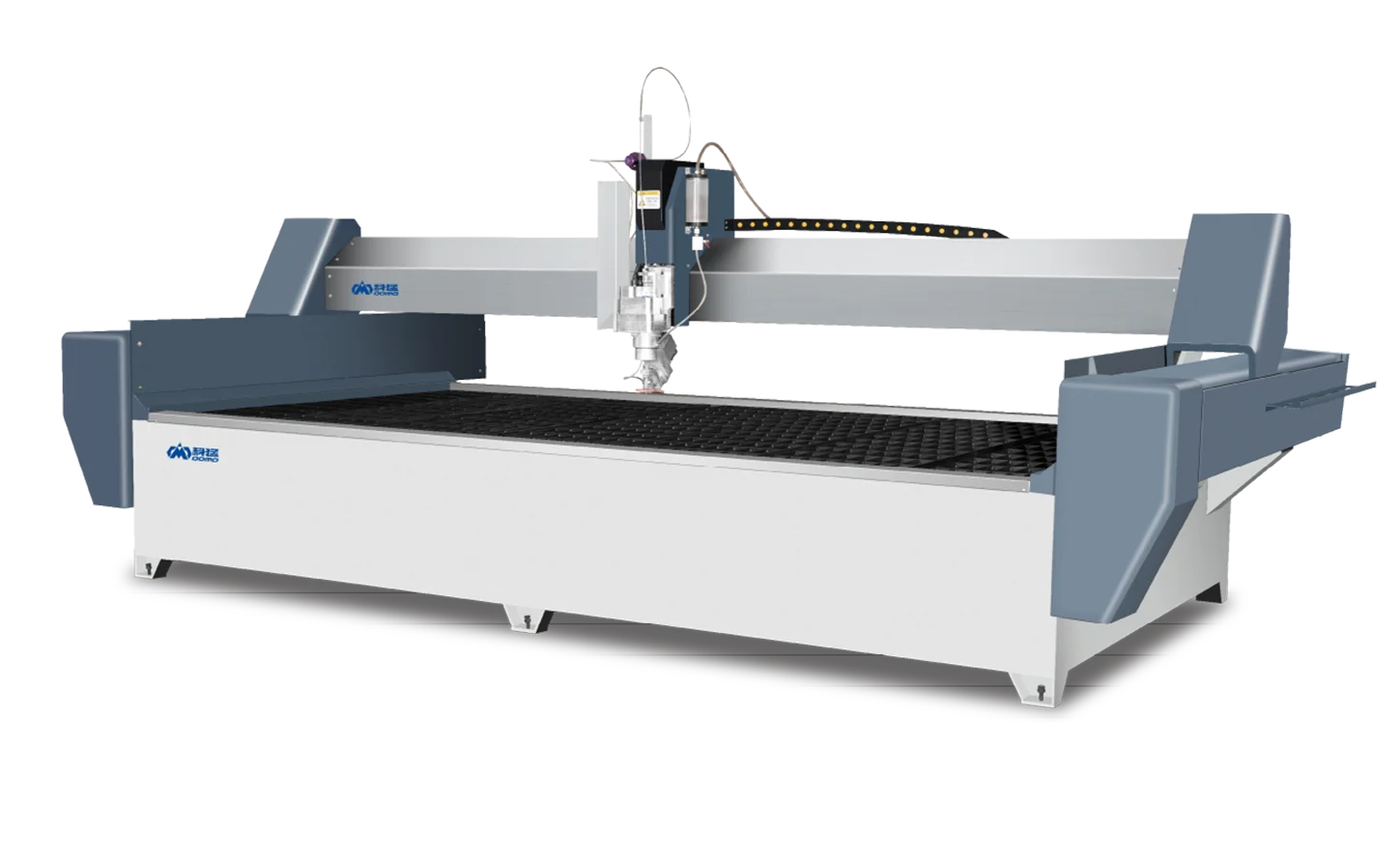

AC 5 Axis CNC Waterjet Cutting Machine(4020AC)

A flagship model for large-format slab cutting, edge profiling, and mitre processing. Perfectly suited for interior applications involving porcelain, sintered stone, and decorative materials.

- 5-axis full interpolation cutting for seamless joint creation and artistic angles

- Auto nesting and intelligent toolpath optimization to reduce waste

- Supports porcelain, sintered stone, glass, MDF, and composites

Talk to Our Expert Sales Team

Whether you need a single-head rock drilling cutter with CAD support or a complete CNC stone machine for basin hole and countertop fabrication, we’re here to help you scale with precision.

Recommended Reading

Expand your knowledge about CNC stone machinery with these expert guides: