CNC Machines for Bathroom Vanity, Sink Cutouts, and Wall Panel Cutting

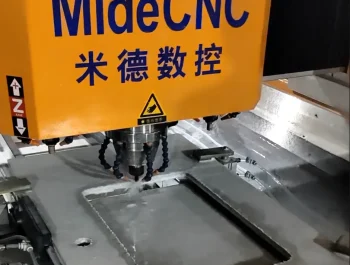

What Can Be Done with Midecnc CNC Machines?

Midecnc CNC machines empower bathroom manufacturers to handle complex designs, materials, and finishes with efficiency and accuracy. Whether it’s precision cutouts for sinks, seamless mitre edges for countertops, or decorative engraving on ceramic panels, our solutions streamline production and enhance design flexibility.

Typical Bathroom CNC Applications

Vanity Top Fabrication

Seamless mitre-cutting, edging, and polishing for custom countertops.

Sink & Faucet Cutouts

Automated drilling for sinks, faucets, and drainage holes.

Wall Panel Processing

Large slab cutting and seamless panel joining for bathroom walls.

Artistic Surface Engraving

Seamless mitre-cutting, edging, and polishing for custom countertops.

Anti-slip Groove Milling

Milling shallow grooves to improve shower safety and traction

Fixture Slot Milling

Milling recesses for concealed fixture mounting (e.g., cabinets, brackets).

Typical Processing Capabilities

Sink Cutouts

Automatic sink hole drilling and inner contour cutting

Vanity Tops

Precise mitre cutting for seamless bathroom counters

Wall Panels

Large slab cutting for shower walls or wet areas

Engraved Details

Laser-like engraving of patterns on stone or porcelain

Anti-slip Grooves

Shallow trench cutting for shower base to prevent slipping

Hole Drilling

Automated round/square hole drilling

Application Gallery

Explore real-world applications of Midecnc machines in the bathroom industry — from stone countertop production to artistic engraving. These case studies showcase how our CNC solutions bring precision, efficiency, and creative flexibility to every processing task.

Large-format Stone Vanity Top Production

A complete production workflow from slab loading, sink cutouts, to 45° mitre edge processing. This solution is perfect for high-end custom vanity tops, combining strength, precision, and seamless joints.

- Supports both straight and 45° mitre cuts for seamless countertop assembly

- High-speed drilling and contour cutting for round or custom-shaped sinks

- Smooth edge polishing enhances visual and tactile quality

Integrated Wall Panel Cutting

Cutting large porcelain slabs into shower wall sizes with minimal material waste.

Sink & Faucet Drilling Automation

Automated drilling of sink holes, faucet openings, and installation slots.

Artistic Surface Engraving

Custom engraving on ceramic tiles for decorative wall panels.

Shower Floor Anti-slip Groove Milling

Precision shallow grooves milled on tile or stone surfaces to improve traction in wet zones

Key Technical Advantages

Midecnc’s CNC solutions for the bathroom industry offer industry-leading automation, accuracy, and material compatibility. Whether you’re a custom fabricator or mass producer, our machines are engineered to reduce labor, minimize waste, and boost productivity.

Advantage 1: Integrated Workflow Automation

From slab loading to final edge polishing, one machine handles the entire process with minimal manual intervention.Advantage 2: ±0.02mm Accuracy for Seamless Assembly

High-precision servo systems ensure every part fits together perfectly—ideal for 45° mitre edge joining and multi-panel assembly.Advantage 3: Multi-Material Cutting Flexibility

Compatible with sintered stone, ceramic, porcelain, and glass, enabling broader product development for modern bathroom designs.Advantage 4: Smart Nesting & Waste Reduction

Optimized path planning and nesting software reduce material waste and boost cutting efficiency.

Recommended Machines

Choose the ideal CNC solution tailored for bathroom product fabrication. From vanity top processing to precision engraving, Midecnc offers reliable models for every scale of operation.

CNC Sink Cutout Machine

Automated drilling and routing for sink, faucet, and installation holes.

- Fast cycle times for mass production

- Template and freeform shape compatibility

- Compact layout, easy to integrate

4 Axis CNC Bridge Saw

A powerful and user-friendly CNC bridge saw tailored for bathroom countertop and panel processing. The 4-axis configuration allows mitre cutting, hole shaping, and flexible slab handling, making it an ideal machine for professional stone fabricators.

- 4-axis cutting flexibility: Enables straight, bevel, and circular cuts with high precision

- Integrated hole drilling: Perform faucet, drain, or sink hole cutting in one workflow

- Heavy-duty frame & easy control: Built for stability and intuitive operation

5 Axis CNC Bridge Saw (4020AC)

A powerful all-in-one machine ideal for cutting, mitre processing, and drilling of large-format slabs.

- 5-axis control for advanced bevel and angle cuts

- Automatic tool change for versatile processing

- Suitable for sintered stone, quartz, and ceramic

Trusted by Bathroom Furniture Manufacturers Worldwide

Midecnc’s bridge saw reduced our sink cutout time by 40% — we now handle more orders with less labor.

— Le Minh Stoneworks, Vietnam

Frequently Asked Questions

1. Which stone materials are compatible with Midecnc machines?

Our machines support granite, marble, engineered stone, quartz, and ceramic.

2. Can your CNC cut both sink and faucet holes?

Yes. Sink cutouts and faucet boreholes can be programmed in a single setup.

3. Is sloped drainboard cutting supported?

Absolutely, using our machining center or bridge saw with beveling features.

4. What’s the average accuracy for sink hole cuts?

±0.1mm precision can be achieved with proper tool setup.

5. How long does it take to process a typical countertop?

10–30 minutes depending on material and design complexity.

6. Are your machines compatible with CAD drawings?

Yes. Standard formats like DXF or DWG are supported.

7. Can I integrate polishing in the same process?

Yes. Our machining center supports routing and polishing in one cycle.

8. Do you offer installation and training for new users?

Yes. We provide remote and on-site support globally.