Product Description

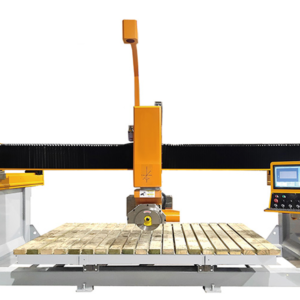

The Single-Head CNC Stone Drilling Machine is purpose-built for fast and accurate drilling, shaping, and processing of granite, quartz stone, rock slabs, and various tabletop surfaces. It is widely used in sink hole processing, platform basins, and countertop fabrication.

This drilling solution features roller conveyors for feeding, a precision fixed clamping system with downward pressure, and template-style hole positioning for easy and consistent operation. It supports common geometric templates like circles, ellipses, rectangles, and squares, and offers G-code compatibility for irregular shapes.

With automatic positioning, CAD import capability, and a user-friendly interface, this machine is ideal for workshops aiming to increase efficiency while maintaining high precision and adaptability.

Key Features

-

Specialized for Drilling & Hole Cutting: Perfect for basin holes, countertops, and slab hole processing.

-

Supports CAD & G-code Input: Easily import precise cutting files and designs, including irregular patterns.

-

High Precision: Repeat positioning accuracy up to 0.01 mm, ensuring consistent output.

-

Roller Conveyor Feeding: Easy material movement for streamlined workflow.

-

Template-Based Positioning: Simple to operate with template input for fast learning and minimal training.

-

Automatic Positioning System: Increases accuracy and reduces human error.

-

Versatile Hole Sizes: Supports cutter diameters from φ3.175 – φ12.7 mm.

-

Water-Cooled Spindle: Efficient cooling system ensures continuous, stable performance.

Technical Parameters

| Parameter | Unit | Value |

|---|---|---|

| Max Cutting Size | mm | 1000 × 3000 |

| Feed Height | mm | 200 |

| Max Running Speed (XY Axis) | m/min | 20 |

| Max Running Speed (Z Axis) | m/min | 10 |

| Repeat Positioning Accuracy | mm | 0.01 |

| Workpiece Fixing Mode | — | Pneumatic fixed table |

| Control Method | — | Automatic positioning |

| Spindle Motor Power | kw | 5.5 – 7.5 |

| Spindle Speed | r/min | 6000 – 24000 |

| Cutter Diameter | mm | φ3.175 / 4 / 6 / 8 / 10 / 12.7 |

| Cooling Method | — | Water cooling |

| Total Power | kw | 12 |

| Voltage | V | 380 |

| Machine Dimensions | mm | 2000 × 3300 |

| Gross Weight | kg | 1000 |

❓Frequently Asked Questions (FAQs)

Q1: What materials can this machine drill?

A1: It is suitable for granite, quartz, rock slabs, and other stone tabletops.

Q2: Can it process irregular shapes?

A2: Yes, the machine supports G-code import and CAD input for complex and irregular drilling patterns.

Q3: How are workpieces fixed during drilling?

A3: The machine uses a pneumatic fixed table with downward pressure for stable and secure processing.

Q4: Is it easy to operate?

A4: Yes, it uses a template-type hole input and auto-positioning, making it very user-friendly, even for beginners.

Q5: What cutter sizes are supported?

A5: It supports cutters with diameters of φ3.175 / 4 / 6 / 8 / 10 / 12.7 mm.