Uzyskaj nieskazitelne rezultaty cięcia blatów granitowych i marmurowych za pomocą pił mostowych CNC 4+1 i 5 osi.

Blat kuchenny jest sercem każdego projektu remontu domu. Niezależnie od tego, czy pracujesz z granitem, marmurem czy kwarcem, czyste i precyzyjne cięcia są kluczowe dla uzyskania efektów premium. Tradycyjne metody ręcznego cięcia często nie spełniają wymagań nowoczesnego designu, prowadząc do marnotrawstwa materiału i nierównych krawędzi.

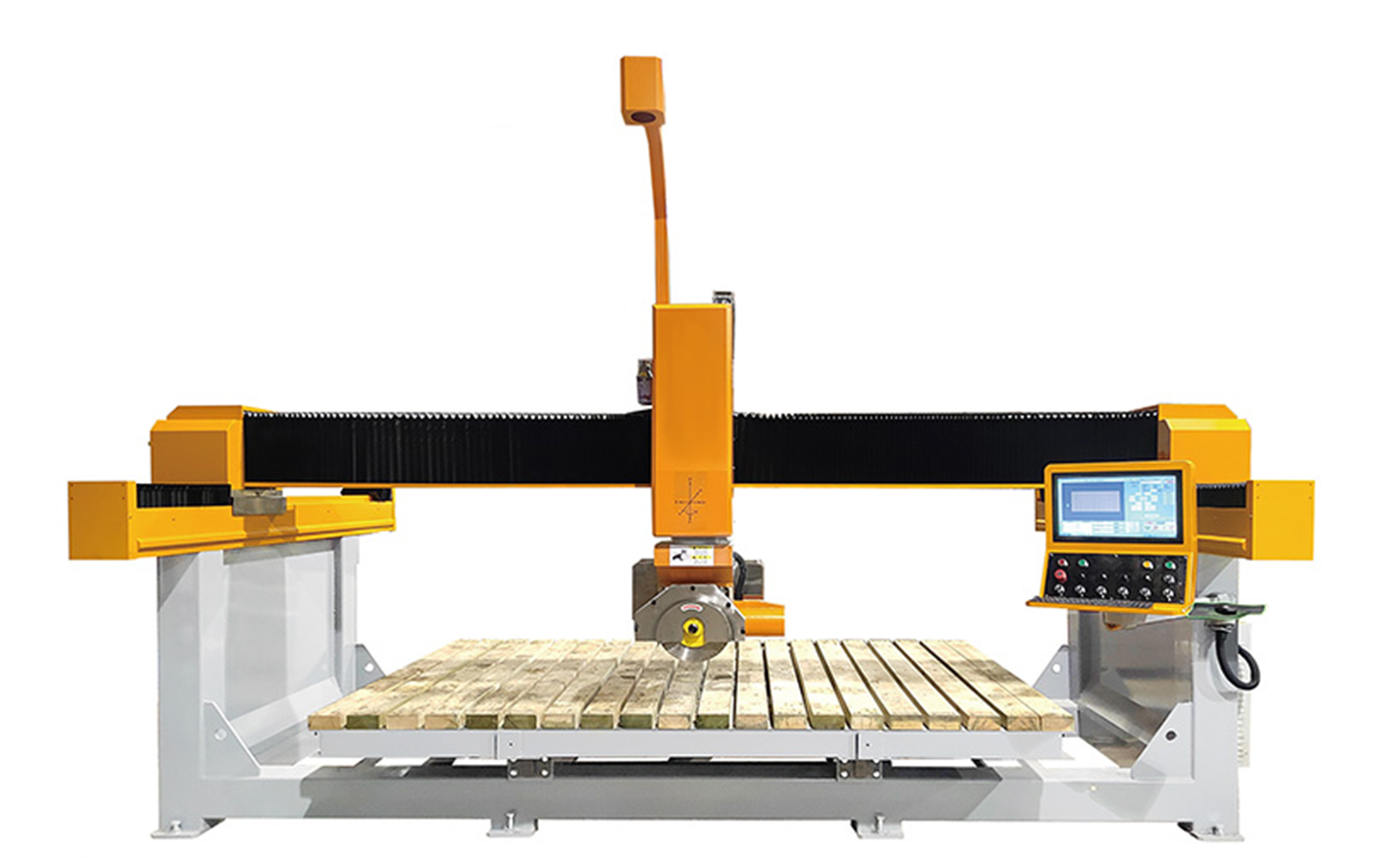

Tutaj wkraczają piły mostowe CNC — łącząc zaawansowaną automatyzację z precyzyjnym cięciem, dostarczają za każdym razem profesjonalnej jakości blatów.

- Jak krok po kroku przygotować i ciąć blaty kamienne

- Kluczowe kwestie bezpieczeństwa

- Polecane modele pił mostowych CNC dla najlepszych rezultatów

Precyzyjne cięcia

Dokładność do ułamków milimetra dla czystych, bezszwowych krawędzi.

Szybsza produkcja

Zautomatyzuj skomplikowane kształty i wycięcia na zlewozmywak, aby przyspieszyć produkcję.

Optymalizacja materiału

Używaj inteligentnego układania, aby zmniejszyć odpady i zmaksymalizować wykorzystanie płyt.

Wszechstronność

Obrabiaj granit, marmur, kwarc i kamień spiekany za pomocą jednej maszyny.

Proces krok po kroku cięcia blatów kamiennych

Pomiar i projektowanie CAD

Zmierz wymiary szafki oraz wycięcia na urządzenia.

Zaprojektuj blat za pomocą oprogramowania CAD (takiego jak AutoCAD lub Alphacam).

Uwzględnij zapasy na występy i profile krawędzi.

Wskazówka: Zawsze podwójnie sprawdzaj pomiary — mierz dwa razy, tnij raz.

Wybór i przygotowanie materiałów

Wybierz wysokiej jakości płyty kamienne bez pęknięć i pustek.

Sprawdź płytę pod kątem jednolitości koloru i integralności strukturalnej.

Ostrożnie załaduj płytę na stół maszyny za pomocą podnośnika próżniowego lub dźwigu.

Konfiguracja piły mostowej CNC

Skalibruj maszynę (prędkość ostrza, prędkość posuwu, głębokość cięcia).

Prześlij swój projekt CAD do systemu sterowania CNC.

Zweryfikuj, czy ścieżka ostrza odpowiada zaprogramowanemu układowi.

Cięcie wstępne

Zacznij od większych cięć, aby oddzielić sekcje blatu.

Użyj laserowego prowadzenia lub systemu pozycjonowania kamerą maszyny do wyrównania.

Precyzyjne cięcie i profilowanie krawędzi

Wykonaj szczegółowe cięcia pod zlewy, krany i otwory na kuchenkę.

Formuj profile krawędzi — zaokrąglone, fazowane, ogee lub niestandardowe style.

Profesjonalna wskazówka: maszyny Midecnc umożliwiają płynne przełączanie między cięciem a frezowaniem za pomocą sterowania 4+1 osi.

Polerowanie i wykończenie

Użyj diamentowych padów polerskich, aby wygładzić powierzchnię.

Uszczelnij blat, aby chronić go przed wilgocią i plamami.

Zalecane modele pił mostowych CNC

Wybierz idealne rozwiązanie CNC dostosowane do produkcji wyrobów łazienkowych. Od obróbki blatów po precyzyjne grawerowanie, Midecnc oferuje niezawodne modele dla każdej skali produkcji.

Piła bramowa CNC 4-osiowa

Potężna i łatwa w obsłudze pilarka mostowa CNC, zaprojektowana do obróbki blatów i paneli łazienkowych. Konfiguracja 4-osiowa umożliwia cięcie pod kątem, wykonywanie otworów i elastyczne zarządzanie płytami – idealna dla profesjonalnych zakładów kamieniarskich.

- Elastyczność cięcia w 4 osiach: Umożliwia precyzyjne cięcia proste, ukośne i okrągłe

- Zintegrowane wiercenie otworów: Wykonuje cięcie otworów na kran, odpływ lub zlew w jednym przebiegu

- Heavy-duty frame & easy control: Built for stability and intuitive operation

5-osiowa piła mostowa CNC

Zaprojektowana z myślą o najbardziej wymagających zastosowaniach wnętrzarskich i architektonicznych, 5-osiowa piła mostowa CNC umożliwia ultraprecyzyjne cięcia ukośne, kształtowanie łuków, wycinanie zlewów, a nawet płaskorzeźby – wszystko w jednym inteligentnym procesie. Przystosowana do pracy z kamieniem spiekanym, marmurem, kwarcem i panelami ceramicznymi, zapewnia niezrównaną wydajność i wszechstronność dla projektantów i wykonawców.

- Photo Taking & Suction Cup System: Advanced alignment and stone stabilization system enhances safety and accuracy.

- Prawdziwe cięcie 5-osiowe: Pełen ruch XYZ z obrotem i nachyleniem wrzeciona do zaawansowanego profilowania 3D, kształtowania krawędzi i cięć pod kątem (do 45°).

- Obsługuje złożone kształty: idealny do cięcia trójkątów, elips, rombów, kół, blatów, stołów i innych.

Porozmawiaj z naszym zespołem ekspertów ds. sprzedaży

Niezależnie od tego, czy potrzebujesz jedno-głowicowego frezu do wiercenia skał z obsługą CAD, czy kompletnej maszyny CNC do produkcji otworów na umywalki i blatów, jesteśmy tutaj, aby pomóc Ci skalować produkcję z precyzją.

Zalecana lektura

Rozszerz swoją wiedzę na temat maszyn CNC do obróbki kamienia dzięki tym przewodnikom ekspertów: