Case Story: A Cyprus Client Transforms Production with Midecnc 5 Axis Waterjet Cutting Machine

A leading stone fabrication company in Cyprus overcomes production limitations and expands capabilities by upgrading to Midecnc's advanced 5-axis waterjet technology, achieving remarkable improvements in precision, efficiency, and project scope.

Customer Background

Based in Limassol, Cyprus, our client operates a leading stone fabrication company specializing in high-end architectural elements for luxury hotels, resorts, and residential properties. With over 15 years of industry experience, they have built a reputation for exceptional craftsmanship in marble, granite, and engineered stone products.

As their business grew, they began receiving more complex orders requiring intricate cuts and precise detailing that their existing equipment couldn't efficiently produce. Their portfolio expanded to include custom stone furniture, decorative panels, and architectural features requiring complex angles and curves.

Challenges Faced

The client faced several critical challenges with their previous 3-axis waterjet system and traditional cutting tools:

- Inability to produce complex 3D contours and compound angles required for modern designs

- Maximum material thickness limitation of 100mm, restricting project possibilities

- Poor edge quality on brittle materials like marble, requiring extensive secondary finishing

- Slow cutting speeds (maximum 500 mm/min) for intricate patterns

- Inconsistent cut precision (±0.15mm tolerance), causing fitting issues in installation

- High maintenance requirements and frequent downtime

These limitations were preventing them from accepting high-value contracts for luxury projects, particularly those involving complex geometries and premium materials.

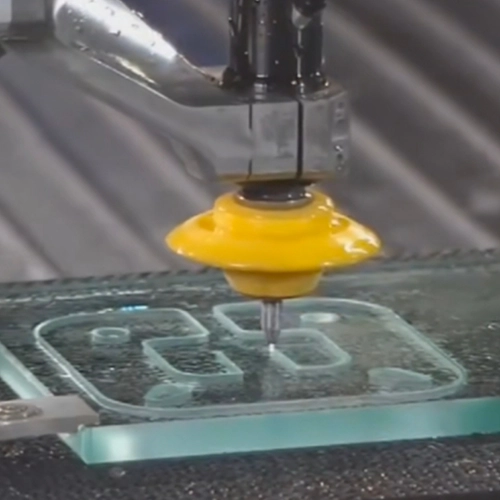

Precision in Action

The Midecnc Solution

After evaluating multiple options, the client selected the Midecnc M5-2030 5 Axis Waterjet Cutting Machine, a premium industrial solution designed for high-precision fabrication across diverse materials.

Core Technical Specifications

The Midecnc solution offered several advanced features that directly addressed the client's challenges:

Key Technological Advantages

- Advanced 5-axis kinematics: High-torque servo motors with backlash elimination ensure precise movement even at maximum extension, enabling complex 3D cuts with compound angles

- Intelligent cutting system: Adaptive pressure control (20,000-60,000 psi) automatically adjusts based on material type and thickness, preserving edge quality while optimizing speed

- Dynamic waterjet technology: Oscillating cutting head reduces taper effect to less than 0.02mm on materials up to 50mm thick

- Integrated abrasive management: Automatic garnet feeding system with precise flow control (0.5-3 kg/min) reduces waste by 30% compared to conventional systems

- SmartVision camera system: Real-time material alignment and automatic contour detection for irregular workpieces, reducing setup time by 40%

- Midecnc OS: Proprietary operating system with material-specific cutting presets and AI-powered path optimization

The machine's robust construction features a heavy-duty steel frame with vibration damping technology, ensuring stable operation even during extended production runs – a critical factor for maintaining precision in large projects.

Seamless Implementation & Training

The Midecnc technical team completed installation within 3 days, including: foundation verification, machine levelling with precision laser alignment, high-pressure system calibration, and integration with the client's existing dust collection system.

A comprehensive 5-day training program was provided for 6 operators and 2 maintenance personnel, covering:

Advanced Operation

5-axis programming, toolpath simulation, material parameter optimization, and precision calibration procedures

Software Mastery

CAD/CAM integration, 3D model importing, custom macro creation, and remote monitoring setup

Preventive Maintenance

High-pressure pump servicing, seal replacement protocols, filter maintenance schedule, and wear part identification

Troubleshooting

Pressure system diagnostics, motion error resolution, software recovery, and remote support utilization

Transformative Results & Client Feedback

Within three months of implementing the Midecnc 5 Axis Waterjet Cutting Machine, the client documented significant operational improvements:

Technical Performance Outcomes

- Cut precision improved from ±0.15mm to ±0.05mm, eliminating fitting issues in installation

- Processing time for complex parts reduced by 58% due to higher cutting speeds and reduced setup time

- Secondary finishing requirements decreased by 72% thanks to superior edge quality

- Material utilization improved from 65% to 92% with nesting optimization software

- Downtime reduced by 80% compared to previous equipment

"The Midecnc 5-axis waterjet has revolutionized our production capabilities. The precision is incredible – we're consistently achieving tolerances below 0.05mm, which was previously impossible. The 5-axis capability allows us to produce complex architectural elements in a single operation that would have required multiple setups before. The adaptive pressure control is a game-changer for working with delicate marbles; we've eliminated chipping entirely. Our operators particularly appreciate the intuitive software interface and material presets that have reduced programming time significantly."

— Managing Director, Cyprus Stone Fabricators

Six months after implementation, the client has expanded their service offerings to include custom 3D stone sculptures and complex architectural features, securing contracts with three luxury hotel chains operating in Cyprus.

Conclusion

This Cyprus client's success story demonstrates how Midecnc's 5 Axis Waterjet Cutting Machine transforms manufacturing capabilities, enabling businesses to take on more complex projects, improve precision, reduce waste, and ultimately increase profitability. The combination of advanced technology, robust construction, and comprehensive support ensures that clients can maximize their investment and stay competitive in demanding markets.

Ready to achieve similar results for your business? Our experts are standing by to help.

Get a Free Consultation via WhatsAppRecommended Machines

For interior decoration professionals, Midecnc offers CNC machines that deliver precision, efficiency, and creative flexibility. Whether you’re working with sintered stone, ceramic panels, or composite materials, our bridge saws and engraving systems are optimized for both artistic detailing and structural fabrication.

5 Axis CNC Bridge Saw

Designed for top-tier interior and architectural applications, the 5-Axis CNC Bridge Saw enables ultra-precise mitre cuts, curve shaping, sink cutouts, and even sculpted reliefs—all in one intelligent workflow. Built for sintered stone, marble, quartz, and ceramic panels, it delivers unmatched efficiency and versatility for designers and fabricators.

- Photo Taking & Suction Cup System: Advanced alignment and stone stabilization system enhances safety and accuracy.

- True 5-Axis Cutting: Offers full XYZ movement with spindle rotation and tilt for advanced 3D profiling, edge shaping, and bevel cuts (up to 45°).

- Handles Complex Shapes: Ideal for cutting triangles, ellipses, diamonds, circles, countertops, tables, and more.

4+1 Axis CNC Bridge Saw

An ideal choice for projects requiring mitre cuts, linear polishing, and embedded slotting. Reliable, fast, and easy to use for everyday interior cutting tasks.

- ±90° blade rotation with 0–90° tilt

- Perfect for cabinet grooves and lighting slot creation

- Heavy-duty frame & easy control: Built for stability and intuitive operation

AC 5 Axis CNC Waterjet Cutting Machine(4020AC)

A flagship model for large-format slab cutting, edge profiling, and mitre processing. Perfectly suited for interior applications involving porcelain, sintered stone, and decorative materials.

- 5-axis full interpolation cutting for seamless joint creation and artistic angles

- Auto nesting and intelligent toolpath optimization to reduce waste

- Supports porcelain, sintered stone, glass, MDF, and composites

Talk to Our Expert Sales Team

Whether you need a single-head rock drilling cutter with CAD support or a complete CNC stone machine for basin hole and countertop fabrication, we’re here to help you scale with precision.