Table of Contents

Product Description

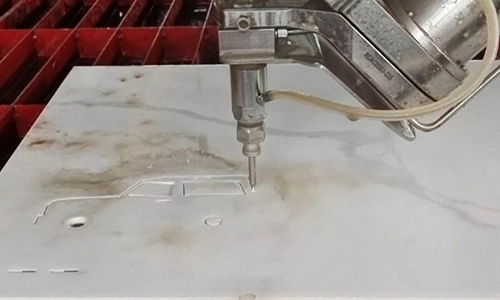

The Midecnc AC 5 Axis CNC Waterjet Cutting Machine delivers next-level precision for industries that demand complex and accurate cutting. Powered by an advanced abrasive waterjet system, this machine handles everything from granite countertops

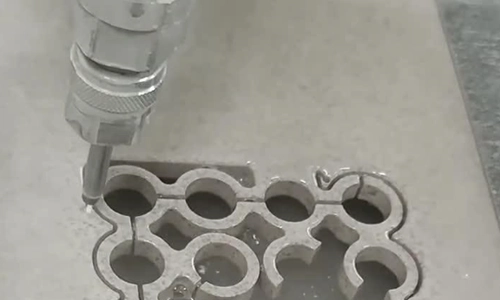

Unlike laser or plasma cutting, waterjet cutting is a cold process — meaning no thermal distortion, no microcracks, and no discoloration. With its robust gantry structure, AC 5-axis bevel head, and industrial CNC controller, this waterjet enables ±65° compound angle cutting, making it ideal for miters, chamfers, 3D profiles, and custom designs.

Whether for stone fabrication shops, metal processing plants, or glass and ceramic manufacturers, this machine sets a new benchmark for efficiency, accuracy, and versatility.

Advanced Waterjet Technology

Key Features

Discover the cutting-edge capabilities of our 5 Axis CNC Waterjet Machine

True AC 5-Axis Bevel Cutting

Supports ±65° tilt for multi-directional compound bevels — perfect for decorative miters, 3D contours, and precision joints.

Ultra-High Precision

Positioning accuracy of ±0.05 mm and repeatability of ±0.02 mm — ideal for aerospace, architectural, and fine-detail cutting.

Heavy-Duty Gantry

Industrial steel frame with vibration-free performance ensures stable, reliable cutting under heavy workloads.

Dual-Pressure Pump System

Switch between high and low pressure to optimize cutting of thin sheets or ultra-thick slabs, reducing energy consumption.

Flexible Thickness Capability

Cuts from 1 mm thin glass to 150 mm thick stone or metal with consistent accuracy.

Smart CAD/CAM Software

DXF/NC compatible with nesting, toolpath optimization, and real-time cutting simulation.

Eco-Friendly Cold Cutting

Zero thermal damage, no fumes, no hazardous waste — safe and sustainable for any workshop.

Low Maintenance

Automatic lubrication, long-life cutting heads, and user-friendly CNC controls reduce downtime and operator training.

Technical Parameters

Detailed specifications of our 5 Axis CNC Waterjet Cutting Machine

| Parameter | Unit | Value |

|---|---|---|

| Cutting Area | mm | 3600 × 1800 |

| Max Workpiece Size | mm | 4100 × 2100 |

| Maximum Cutting Speed | m/min | 8 |

| X/Y Rapid Travel Speed | m/min | 10 |

| Z-Axis Travel Speed | m/min | 3 |

| A/C Axis Rotation Speed | °/sec | 120 |

| Positioning Accuracy | mm/300 mm | ±0.05 |

| Repeatability Accuracy | mm | ±0.02 |

| Max Cutting Thickness* | mm | 150 (stone), 60 (steel), 40 (glass/ceramic) |

| Working Pressure | MPa | 280–360 (Max 450) |

| Water Flow Rate | L/min | 3.7 |

| Cooling System | — | Air-cooled oil system |

| Power Requirement | kW / Voltage | 37 kW / 220–415V |

| Control System | — | Industrial CNC |

| Machine Dimensions | mm | 5200 × 2400 × 2200 |

| Machine Weight | kg | 6200 |

*Material-dependent

Performance Metrics

Cutting Speed Comparison

Max Cutting Thickness by Material

How a Waterjet Cutting Machine Works

Discover the science behind our precision cutting technology

Waterjet Working Principle

High-pressure water stream with optional abrasive

视频加载失败,请检查网络连接

Cutting Process in Action

High-Pressure Generation

The machine's intensifier pump pressurizes water up to 3800–4200 bar (55,000–60,000 psi). This extreme pressure is what gives the waterjet its cutting power.

Jet Formation

The high-pressure water is forced through a tiny jewel orifice (usually sapphire or diamond), converting pressure into a focused, high-velocity jet that can reach speeds of nearly 900 m/s.

Abrasive Mixing (Optional)

For hard materials like granite or metal, fine garnet abrasive is introduced into the water stream in the mixing chamber, forming a powerful cutting jet capable of eroding the material precisely.

Precision Cutting

Controlled by CNC software, the cutting head moves along pre-programmed paths, enabling accurate and smooth cuts without heat distortion or material deformation.

Advantages of Waterjet Cutting

Cold Cutting Process

No thermal damage or distortion

Material Versatility

Cuts almost any material and thickness

High Precision

Accurate cuts with smooth edges

Environmentally Friendly

Minimal waste with water recycling

Applications & Material Capability

Versatile cutting solutions for various industries

Stone Fabrication

- Granite countertops

- Marble flooring

- Porcelain slabs

- Façade cladding

- Sintered stone

Metal Processing

- Stainless steel

- Aluminum

- Copper

- Titanium

- Aerospace parts

- Machine components

Glass Industry

- Architectural glass

- Automotive windshields

- Shower enclosures

- Laminated glass panels

Ceramics & Composites

- Porcelain tiles

- Sanitary ware

- Advanced ceramics

- Carbon fiber

- Plastics

- Rubber

Frequently Asked Questions

Answers to the most common questions about our CNC Waterjet Cutting Machine

Almost all materials including granite, marble, quartz, metal alloys, glass, ceramics, composites, plastics, and carbon fiber.

Yes. The AC 5-axis head supports ±65° tilt for complex miters, chamfers, and 3D profiles.

Up to 150 mm for stone, 60 mm for steel, and 40 mm for glass or ceramics (depending on material type).

Waterjet cutting is a cold process — it avoids heat distortion, hardening, or discoloration, making it safer for fragile and high-value materials.

Yes. It supports DXF/NC formats, nesting, toolpath generation, and 3D angle simulation with a user-friendly interface.

Midecnc provides remote setup guidance, detailed manuals, video tutorials, and optional onsite training for global customers.

Yes, it comes with CE and ISO certifications for compliance in international markets.

Stone CNC Machine Delivery Process

Choose the best way to receive your machine — fast standard delivery or tailored custom solutions, both designed for global stone fabrication businesses.

Standard Delivery Process

Speedy Free Quotation

Get a fast, no-obligation quote tailored to your stone CNC machine needs.

Confirm Order Details

Finalize specifications, payment, and delivery terms with full transparency.

Production Readiness

Your machine enters production immediately with strict quality control.

Transparent Shipping

Real-time logistics tracking ensures safe and timely delivery worldwide.

Custom Delivery Process

Requirement Submission

Share your project details, stone materials, and special cutting requirements.

Quotation and Samples

Receive a customized quotation, with cutting test samples if needed.

Confirm Order Details

Confirm machine configuration, customization options, and production timeline.

Production and Delivery

Your tailor-made machine is manufactured and shipped with reliable global logistics.

GET IN TOUCH

Let's get in touch

Message

Our Contact

Email Address

sally@midecnc.com

Call Us

+8615594977687