CNC Bridge Saw FAQ

Your comprehensive guide to CNC bridge saws for stone fabrication

In modern stone fabrication, CNC bridge saws are essential for cutting marble, granite, quartz, and sintered stone with precision and efficiency. Whether you are a beginner or an experienced fabricator, this FAQ answers common questions about operation, selection, and maintenance.

1 What Is a CNC Bridge Saw?

A CNC bridge saw is a computer-controlled cutting machine designed to process stone slabs with high precision. The bridge design allows the cutting head to travel across large slabs while software automates accurate cuts.

Ideal for both mass production and custom projects, CNC bridge saws reduce human error and increase throughput.

2 What Materials Can a CNC Bridge Saw Cut?

Common materials include:

Marble

Used for countertops, tiles, and decorative pieces. CNC cutting preserves natural veining.

Granite

Durable option for kitchen/bathroom surfaces. CNC ensures clean cuts on hard granite.

Quartz

Engineered stone for interiors. CNC enables precise custom shapes.

Sintered Stone

Modern material for flooring/wall cladding. Requires stable CNC cutting.

3 What Is the Difference Between a 4 Axis and 5 Axis CNC Bridge Saw?

- 4 Axis: Straight and angle cutting, profiling and shaping. Great for countertops and standard fabrication.

- 4+1 Axis: Adds a rotational axis for mitre and compound-angle cuts—good balance of cost and capability.

- 5 Axis: Full 3D machining for complex shapes and curved surfaces—used for advanced projects.

4 How Accurate Are CNC Bridge Saws?

CNC bridge saws typically achieve millimeter-level accuracy (often ±0.1–0.3mm) depending on machine class and calibration.

Proper fixturing, calibration and maintenance are essential to keep accuracy over time.

Close-up of a smooth, precise edge (minimal manual polishing required)

5 What Software Do CNC Bridge Saws Use?

Common choices:

- Stone-focused CAM (TopSolid Stone, AlphaCAM Stone)

- General CAD/CAM (AutoCAD, Fusion 360 with stone plugins)

6 How Much Maintenance Does a CNC Bridge Saw Require?

Typical weekly checks (1–2 hours):

Check Water Cooling

Prevent overheating

Inspect Blades/Spindles

Ensure sharpness

Clean Dust Filters

Maintain air quality

Calibrate Axes

Preserve precision

7 Can CNC Bridge Saws Cut Sintered Stone?

Yes. Sintered stone needs stable, low-vibration cutting; advanced machines use high-torque spindles, damping structures and blades specialized for sintered materials.

- High-torque spindles

- Vibration damping

- Specialized blades

8 What Are the Benefits of Using a CNC Bridge Saw?

High Precision

Millimeter-level cuts reduce waste and ensure consistency.

Faster Production

Automation reduces project time significantly.

Reduced Waste

Precise toolpaths minimize scrap.

Complex Shapes

5-axis models enable advanced 3D designs.

Conclusion

CNC bridge saws bring precision, speed and flexibility to stone fabrication. Explore Midecnc's 4+1 and 5-axis bridge saws to find the right fit for your shop.

Recommended Machines

For interior decoration professionals, Midecnc offers CNC machines that deliver precision, efficiency, and creative flexibility. Whether you’re working with sintered stone, ceramic panels, or composite materials, our bridge saws and engraving systems are optimized for both artistic detailing and structural fabrication.

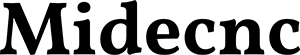

5 Axis CNC Bridge Saw

Designed for top-tier interior and architectural applications, the 5-Axis CNC Bridge Saw enables ultra-precise mitre cuts, curve shaping, sink cutouts, and even sculpted reliefs—all in one intelligent workflow. Built for sintered stone, marble, quartz, and ceramic panels, it delivers unmatched efficiency and versatility for designers and fabricators.

- Photo Taking & Suction Cup System: Advanced alignment and stone stabilization system enhances safety and accuracy.

- True 5-Axis Cutting: Offers full XYZ movement with spindle rotation and tilt for advanced 3D profiling, edge shaping, and bevel cuts (up to 45°).

- Handles Complex Shapes: Ideal for cutting triangles, ellipses, diamonds, circles, countertops, tables, and more.

4+1 Axis CNC Bridge Saw

An ideal choice for projects requiring mitre cuts, linear polishing, and embedded slotting. Reliable, fast, and easy to use for everyday interior cutting tasks.

- ±90° blade rotation with 0–90° tilt

- Perfect for cabinet grooves and lighting slot creation

- Heavy-duty frame & easy control: Built for stability and intuitive operation

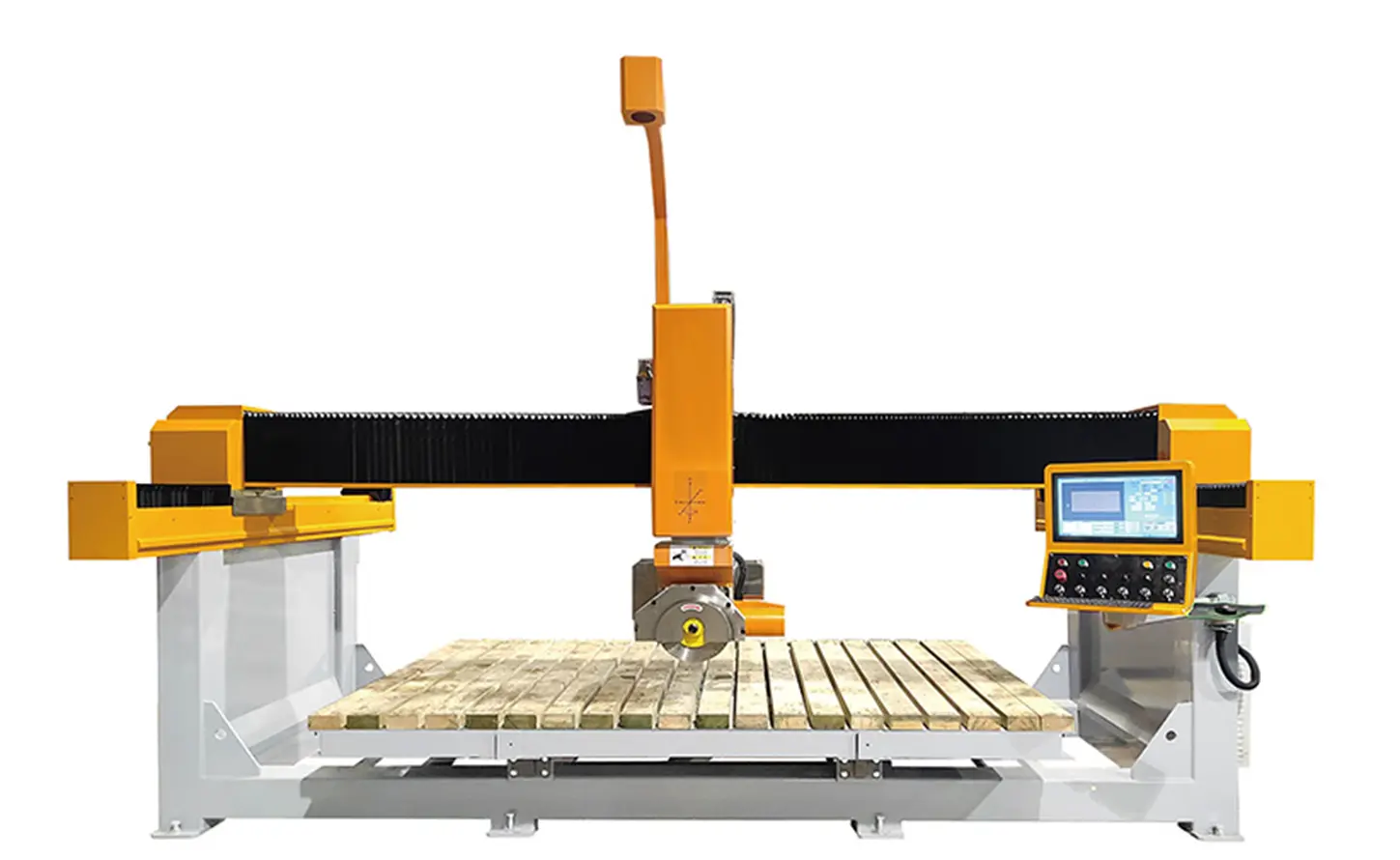

AC 5 Axis CNC Waterjet Cutting Machine(4020AC)

A flagship model for large-format slab cutting, edge profiling, and mitre processing. Perfectly suited for interior applications involving porcelain, sintered stone, and decorative materials.

- 5-axis full interpolation cutting for seamless joint creation and artistic angles

- Auto nesting and intelligent toolpath optimization to reduce waste

- Supports porcelain, sintered stone, glass, MDF, and composites

Talk to Our Expert Sales Team

Whether you need a single-head rock drilling cutter with CAD support or a complete CNC stone machine for basin hole and countertop fabrication, we’re here to help you scale with precision.

Recommended Reading

Expand your knowledge about CNC stone machinery with these expert guides: