Achieve flawless results with granite and marble countertop cutting using 4+1 and 5 axis CNC bridge saws.

The kitchen countertop is the heart of any home renovation project. Whether you are working with granite, marble, or quartz, achieving clean, precise cuts is essential for high-end results. Traditional manual cutting methods often struggle to meet modern design demands, leading to wasted materials and uneven edges.

This is where CNC bridge saws come in—combining advanced automation with precision cutting to deliver professional-quality countertops every time.

- How to prepare and cut stone countertops step by step

- Key safety considerations

- Recommended CNC bridge saw models for the best results

Precision Cuts

Accurate to within fractions of a millimeter for clean, seamless edges.

Faster Production

Automate complex shapes and sink cutouts to speed up fabrication.

Material Optimization

Use intelligent nesting to reduce waste and maximize slab usage.

Versatility

Process granite, marble, quartz, and sintered stone with one machine.

Step-by-Step Process for Cutting Stone Countertops

Measurement & CAD Design

Measure cabinet dimensions and any appliance cutouts.

Design the countertop using CAD software (such as AutoCAD or Alphacam).

Include allowances for overhangs and edge profiles.

Tip: Always double-check measurements—Measure Twice, Cut Once.

Material Selection & Preparation

Choose high-quality stone slabs free of cracks or voids.

Inspect the slab for color consistency and structural integrity.

Load the slab carefully onto the machine table using a vacuum lifter or crane.

CNC Bridge Saw Setup

Calibrate the machine (blade speed, feed rate, depth of cut).

Upload your CAD design to the CNC control system.

Verify that the blade path matches the programmed layout.

Rough Cutting

Start with larger cuts to separate sections of the countertop.

Use the machine’s laser guide or camera positioning system for alignment.

Precision Cutting & Edge Profiling

Perform detailed cuts for sinks, faucets, and stove openings.

Shape the edge profiles—bullnose, bevel, ogee, or custom styles.

Pro Tip: Midecnc machines allow you to switch seamlessly between cutting and milling with 4+1 axis control.

Polishing & Finishing

Use diamond polishing pads to refine the surface.

Seal the countertop to protect against moisture and staining.

Recommended CNC Bridge Saw Models

Choose the ideal CNC solution tailored for bathroom product fabrication. From vanity top processing to precision engraving, Midecnc offers reliable models for every scale of operation.

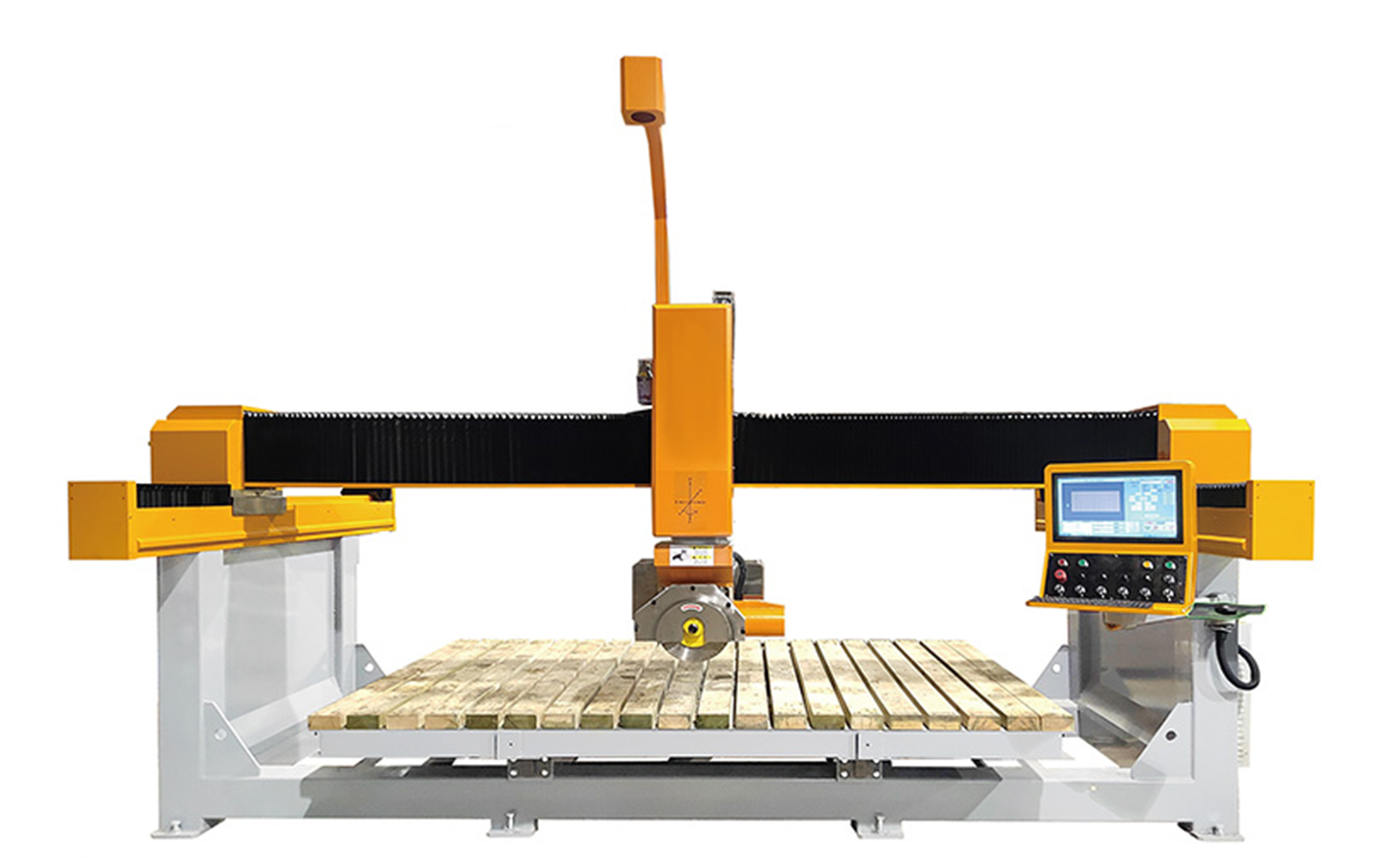

4 Axis CNC Bridge Saw

A powerful and user-friendly CNC bridge saw tailored for bathroom countertop and panel processing. The 4-axis configuration allows mitre cutting, hole shaping, and flexible slab handling, making it an ideal machine for professional stone fabricators.

- 4-axis cutting flexibility: Enables straight, bevel, and circular cuts with high precision

- Integrated hole drilling: Perform faucet, drain, or sink hole cutting in one workflow

- Heavy-duty frame & easy control: Built for stability and intuitive operation

5 Axis CNC Bridge Saw

Designed for top-tier interior and architectural applications, the 5-Axis CNC Bridge Saw enables ultra-precise mitre cuts, curve shaping, sink cutouts, and even sculpted reliefs—all in one intelligent workflow. Built for sintered stone, marble, quartz, and ceramic panels, it delivers unmatched efficiency and versatility for designers and fabricators.

- Photo Taking & Suction Cup System: Advanced alignment and stone stabilization system enhances safety and accuracy.

- True 5-Axis Cutting: Offers full XYZ movement with spindle rotation and tilt for advanced 3D profiling, edge shaping, and bevel cuts (up to 45°).

- Handles Complex Shapes: Ideal for cutting triangles, ellipses, diamonds, circles, countertops, tables, and more.

Talk to Our Expert Sales Team

Whether you need a single-head rock drilling cutter with CAD support or a complete CNC stone machine for basin hole and countertop fabrication, we’re here to help you scale with precision.

Recommended Reading

Expand your knowledge about CNC stone machinery with these expert guides: