Whether you work with marble, granite, or quartz stone, choosing the right CNC stone machinery can make the difference between average results and exceptional craftsmanship. At Midecnc, we specialize in advanced CNC stone cutting and processing solutions that help workshops streamline production, reduce material waste, and achieve flawless results. Let's explore the five essential types of CNC stone machinery every professional workshop should know.

Table of Contents

Recommended Tools

Diamond Cutting Blades

High-quality blades for precise cutting

CNC Router Bits

Specialized bits for stone engraving

Polishing Pads

For perfect finishes on stone surfaces

1. CNC Bridge Saw

A CNC bridge saw is the cornerstone of most stone fabrication workshops. Designed for cutting large slabs of granite, marble, and engineered stone, bridge saws deliver straight, angled, and curved cuts with perfect consistency.

Midecnc's 4+1 Axis and 5 Axis Bridge Saws allow fabricators to perform sink cutouts, beveling, and mitre cuts with high accuracy. They are ideal for kitchen countertops, wall claddings, and flooring projects.

The automatic positioning and tilting head of modern bridge saws ensure precise cutting even for complex shapes. With smart cutting path optimization, these machines minimize material waste while maximizing efficiency.

Compatible with advanced CAD/CAM software, CNC bridge saws can easily translate digital designs into physical stone products, making them indispensable for custom fabrication work.

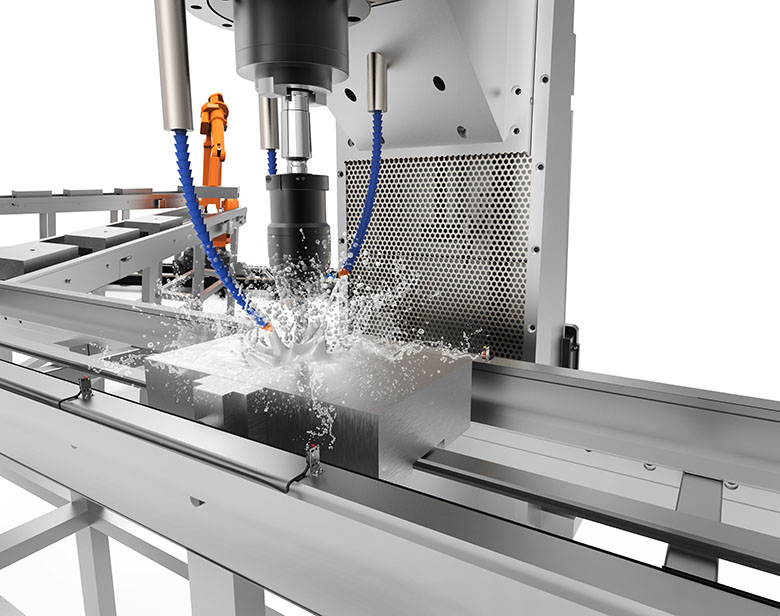

2. CNC Waterjet Cutting Machine

When precision meets versatility, waterjet cutting becomes the hero of stone processing. A CNC waterjet cutting machine uses ultra-high-pressure water (sometimes mixed with abrasive garnet) to cut thick marble, granite, ceramics, glass, and metal—without heat distortion.

Compared to traditional saws, waterjets achieve ultra-smooth edges and intricate patterns, perfect for artistic inlays and decorative stone projects. The cold cutting process eliminates thermal damage, preserving the natural integrity of the material.

CNC waterjet machines can cut materials up to 100 mm thickness with remarkable precision, making them suitable for both thin decorative pieces and thick structural components.

The ability to cut almost any material with the same machine makes waterjet cutting a versatile addition to any stone workshop, especially those handling custom or artistic projects.

3. CNC Stone Engraving Machine

If your workshop handles memorials, reliefs, or 3D sculptures, a CNC stone engraving machine is indispensable. These machines use high-speed spindles and diamond tools to engrave precise text, patterns, or relief designs on marble and granite surfaces.

With digital control, operators can easily reproduce complex artworks with perfect repeatability—something impossible with manual carving. The high-precision spindle ensures fine details are captured accurately, even in hard materials like granite.

Modern CNC stone engraving machines offer both 2D and 3D engraving capabilities, allowing for a wide range of creative possibilities. From simple text engraving to complex 3D sculptures, these machines expand the creative potential of any stone workshop.

The stable structure of these machines minimizes vibration during operation, ensuring clean, precise cuts even at high speeds. This stability is crucial for achieving professional results in decorative and artistic stonework.

4. Stone Polishing Machine

After cutting and shaping comes the most critical step—polishing. A stone polishing machine refines the surface, bringing out the natural shine and texture of marble or granite.

Midecnc's CNC polishing equipment ensures uniform pressure and smooth motion, delivering mirror-like finishes across all surfaces. Whether you're polishing edges, sinks, or full slabs, CNC automation saves labor while improving quality.

Automatic pressure control allows the machine to adapt to different material thicknesses and hardness levels, ensuring consistent results even across irregular surfaces. This adaptability is particularly valuable when working with natural stone, which can vary significantly in density.

The adjustable polishing head can be configured for different finishes, from matte to high-gloss, giving workshops the flexibility to meet diverse customer requirements. Consistent, repeatable finishes are essential for maintaining a professional reputation in the stone fabrication industry.

5. CNC Drilling Center

Finally, the CNC drilling and milling center is your go-to for complex countertop fabrication. It handles sink holes, faucet holes, drain grooves, and edge profiling with exceptional precision.

A CNC drilling center can easily manage both vertical and horizontal drilling, making it essential for quartz and granite countertop production. The multi-axis control allows for complex 3D shaping, enabling the creation of intricate edge profiles and custom designs.

Integrated tool magazines enable fast tool changes, reducing setup time and increasing productivity. This feature is particularly valuable for workshops handling a variety of projects with different tooling requirements.

The precision of CNC drilling centers ensures perfect alignment of holes and edges, eliminating the inconsistencies that can occur with manual drilling. This level of accuracy is crucial for achieving professional results in countertop fabrication and other precision stonework.

Choosing the Right CNC Stone Machine for Your Workshop

Each type of CNC stone machinery serves a specific role—from rough slab cutting to fine detailing and final polishing. A well-equipped workshop often combines several machines to handle every production stage efficiently.

If you mainly process granite and quartz, focus on bridge saws and drilling centers for heavy-duty tasks. For decorative or artistic projects, pair a waterjet cutter with a stone engraving machine. And don't forget that polishing systems ensure every piece leaves your workshop in perfect condition.

Ready to Enhance Your Stone Fabrication Capabilities?

Discover how Midecnc's advanced CNC stone machinery can transform your workshop's productivity and precision.