Table of Contents

Product Description

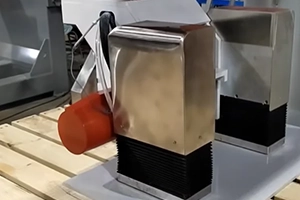

The 4-Axis Bridge Cutting CNC Machine (4+1) is a high-end solution for precision stone processing, designed for cutting, profiling, and shaping a wide range of materials including marble, granite, quartz stone, ceramic tiles, and cement-based slabs.

Featuring a robust bridge-type integrated structure, it ensures long-term rigidity, stability, and reliable performance under heavy workloads. The X, Y, and Z axes employ precision linear guides for smooth motion and high accuracy. The spindle head rotates 360° with real-time stepless speed control, paired with an automatic tool setting system, enabling fast and precise edge cutting, chamfering, and profiling.

The CNC system supports CAD file imports and smart interface controls, enabling fast production setup for irregular shapes like triangles, polygons, circles, ellipses, diamonds, and decorative table panels. With optimized energy-saving features, it reduces power consumption by up to 30%, ensuring cost-effective operation.

4-Axis Bridge Cutting CNC Machine

Key Features

Discover the cutting-edge capabilities of our 4-Axis Bridge Cutting CNC Machine

4+1 Axis CNC Configuration

360° spindle rotation enables advanced curve and arc processing for complex shapes and profiles.

Heavy-Duty Bridge Structure

High-load capacity for large stone slabs, ensuring long-term stability and precision.

Precision Linear Guides

Smooth, accurate motion for X, Y, and Z axes for high precision cutting and profiling.

Automatic Tool Setting

Minimizes manual errors and boosts efficiency with automated tool positioning.

Real-Time Stepless Speed Control

Ensures precision under varying material types and shapes with adjustable speed settings.

CAD File Compatibility

Easily import drawings and execute complex cutting patterns with advanced CNC software.

Energy Efficient

Intelligent servo control saves up to 30% electricity compared to conventional machines.

Supports Various Stone Types

Versatile processing capabilities for marble, granite, quartz stone, cement boards, ceramic tiles, and more.

Technical Parameters

Detailed specifications of our 4-Axis Bridge Cutting CNC Machine

| Parameter | Unit | Value |

|---|---|---|

| Max. Cutting Size | mm | 3200 × 2000 |

| Feed Height | mm | 100 |

| Max. Running Speed (X/Y) | mm/min | 20000 |

| Max. Running Speed (Z) | mm/min | 3000 |

| Repeat Positioning Accuracy | mm | 0.1 |

| Spindle Speed | r/min | 18000 |

| Cutter Diameter | mm | 350–400 |

| Cutting Tool Cooling | — | Water |

| Total Power | kW | 20 |

| Voltage | V | 380 |

| Machine Dimension | mm | 5000 × 2800 |

| Gross Weight | kg | 4000 |

| Spindle Motor Power | kW | 11 kW / 15 kW (optional) |

| Control System | — | Intelligent Control System |

| Workpiece Fixed Way | — | Fixed Platform |

Performance Metrics

Cutting Speed Comparison

Material Processing Capability

Optional Accessories

Enhance your machine capabilities with these optional accessories

Industrial Camera System (CCD Vision)

Automatically detects stone texture, flaws, and cutting areas for optimized layout and tool path planning.

Benefits:

- Improves production efficiency

- Reduces manual intervention

- Ensures cutting accuracy

Suction Cup System

Equipped with high-capacity suction cups for automatic stone handling and positioning.

Benefits:

- Reduces manual labor

- Increases safety

- Prevents slab damage

Optional Spindle Upgrade

Higher power spindle (15kW optional) for faster cutting and improved efficiency.

Benefits:

- Faster cutting speeds

- Improved efficiency

- Better performance with hard materials

Configuration Recommendation

| Accessory Type | Function Description | Recommended Reason |

|---|---|---|

| Industrial Camera | Detects texture & optimizes layout | Increases cutting accuracy, reduces manual setup |

| Suction Cup System | Automatic handling and positioning | Enhances safety and efficiency |

| Spindle Upgrade | Faster cutting & high-load capability | Improves efficiency for heavy-duty materials |

Applications & Material Capability

Versatile cutting solutions for various industries

Applications

- Custom Stone Fabrication: Kitchen countertops, vanity tops, decorative panels.

- Architectural Elements: Flooring, wall cladding, staircases, facades.

- Decorative Design: Complex shapes, polygons, ellipses, circles, diamonds.

- Industrial Workshops: Mass production with precision edge finishing and profiling.

Material Capability

- Marble: Polished, honed, natural edges.

- Granite: High-strength slabs and heavy-duty applications.

- Quartz Stone: Engineered surfaces and composite panels.

- Ceramic Tiles: Precise cutting for interior decoration.

- Cement-Based Slabs & Composite Materials: High-load cutting and profiling.

Marble

Granite

Quartz

Ceramic

Frequently Asked Questions

Answers to the most common questions about our 4-Axis Bridge Cutting CNC Machine

The machine can cut marble, granite, quartz stone, ceramic tiles, cement products, and other building materials with high precision and efficiency.

Yes, the machine supports CAD file imports and complex patterns like arcs, circles, ellipses, polygons, and decorative designs.

The machine features X, Y, Z axes plus 360° spindle rotation and one additional controlled axis for more complex movements and profiles.

Yes, it features an automatic tool setting system that enhances processing precision and reduces manual errors.

Yes, it can save up to 30% electricity with intelligent servo control compared to conventional CNC machines.

The machine can handle a maximum cutting size of 3200 × 2000 mm, suitable for large stone slabs and panels.

The spindle speed is 18000 r/min with real-time stepless speed control for optimal performance with different materials.

Stone CNC Machine Delivery Process

Choose the best way to receive your machine — fast standard delivery or tailored custom solutions, both designed for global stone fabrication businesses.

Standard Delivery Process

Speedy Free Quotation

Get a fast, no-obligation quote tailored to your stone CNC machine needs.

Confirm Order Details

Finalize specifications, payment, and delivery terms with full transparency.

Production Readiness

Your machine enters production immediately with strict quality control.

Transparent Shipping

Real-time logistics tracking ensures safe and timely delivery worldwide.

Custom Delivery Process

Requirement Submission

Share your project details, stone materials, and special cutting requirements.

Quotation and Samples

Receive a customized quotation, with cutting test samples if needed.

Confirm Order Details

Confirm machine configuration, customization options, and production timeline.

Production and Delivery

Your tailor-made machine is manufactured and shipped with reliable global logistics.

GET IN TOUCH

Let's get in touch

Message

Our Contact

Email Address

sally@midecnc.com

Call Us

+8615594977687