Table of Contents

Product Description

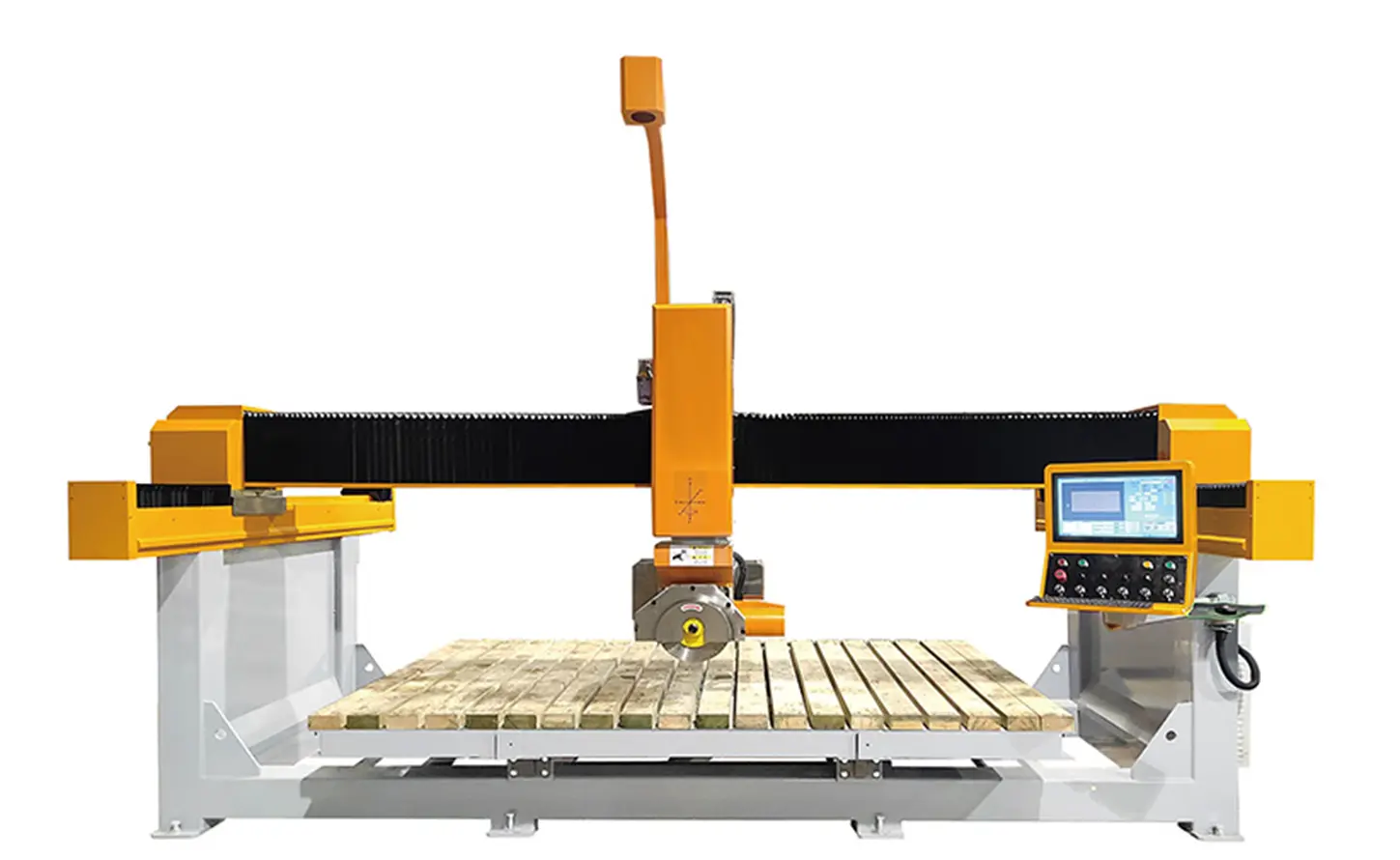

The Midecnc 5 Axis CNC Bridge Cutting Machine is a next-generation stone fabrication system built for precision, efficiency, and flexibility. With full five-axis simultaneous control, it performs straight, curved, circular, and arc cuts, as well as complex 3D profiling, beveling (up to 45°), drilling, and hole cutting—all with outstanding accuracy and speed.

Equipped with a permanent magnet spindle, absolute value servo motors, and high-precision linear guide rails, this machine delivers long-term stability, high torque, and smooth motion. Its intelligent touchscreen CNC system supports DXF file import, automatic path generation, photo alignment, and suction-cup positioning, allowing operators to complete jobs faster and with minimal setup.

Compared with traditional bridge saws, it saves up to 30% energy thanks to optimized servo drive systems and smart electronic control, making it ideal for modern workshops that demand automation, performance, and sustainability.

Advanced Bridge Cutting Technology

Key Features

Discover the cutting-edge capabilities of our 5 Axis CNC Bridge Cutting Machine

True 5-Axis Motion

Full XYZ travel with rotation and tilt, supporting intricate beveling and 3D contouring for complex shapes.

Smart Touchscreen CNC Control

Intuitive interface with visual programming and real-time path monitoring for efficient operation.

DXF File Support

Import designs directly; no manual coding required for faster setup and production.

Permanent Magnet Spindle

Delivers stable torque and smooth operation at 3000–6000 rpm for consistent cutting performance.

Absolute Value Servo Motors

High-precision feedback with automatic positioning memory for accurate repeatability.

Photo Alignment & Suction Cup System

Enhances setup accuracy and stone stability during cutting for improved safety and quality.

Energy-Efficient Design

Reduces power use by up to 30% compared with traditional bridge saws for cost savings.

Versatile Cutting Capability

Easily handles straight edges, arcs, ellipses, diamonds, and custom shapes with precision.

Technical Parameters

Detailed specifications of our 5 Axis CNC Bridge Cutting Machine

| Parameter | Unit | Value |

|---|---|---|

| Max. Cutting Size | mm | 3500 × 2000 (Customizable) |

| Feed Height | mm | 260 |

| Max. Running Speed (X/Y) | mm/min | 30000 |

| Max. Running Speed (Z) | mm/min | 6000 |

| Repeat Positioning Accuracy | mm | 0.1 |

| Spindle Motor Speed | r/min | 3000 – 6000 |

| Cutter Diameter | mm | 350 – 700 |

| Cooling Method | — | Water |

| Control System | — | Touchscreen CNC / CUT CAM |

| Voltage | V | 380 |

| Total Power | kW | 20 |

| Spindle Power | kW | 15 / 22 (optional) |

| Machine Dimension | mm | 5400 × 3900 |

| Gross Weight | kg | 4000 |

| Workpiece Fixing | — | Fixed Table + Suction |

Performance Metrics

Cutting Speed Comparison

Material Processing Capabilities

Applications & Materials

Versatile cutting solutions for various industries

Natural Stones

- Marble

- Granite

- Sandstone

- Limestone

Engineered Stones

- Quartz

- Artificial marble

- Sintered stone

Ceramics & Composites

- Porcelain slabs

- Ceramic tiles

- Carbon fiber panels

Cement-based & Hybrid Materials

- Terrazzo

- Concrete slabs

- Fiber cement boards

Typical Applications

Kitchen & Bathroom Countertops

Staircases & Flooring

Wall Cladding & Facades

Fireplace Surrounds

Tabletops

Furniture

Decorative Stoneworks

Frequently Asked Questions

Answers to the most common questions about our CNC Bridge Cutting Machine

It can cut marble, granite, quartz stone, porcelain, sintered stone, concrete slabs, and more.

Straight, circular, curved, elliptical, diamond-shaped, drilled holes, 45° bevels, and countertop profiling.

No. The system reads DXF files directly and automatically generates the tool path.

It holds the slab firmly in place while photo alignment ensures accurate positioning and safe operation.

Yes. Midecnc's advanced servo drives and permanent magnet motors reduce energy consumption by about 30% versus conventional systems.

Stone CNC Machine Delivery Process

Choose the best way to receive your machine — fast standard delivery or tailored custom solutions, both designed for global stone fabrication businesses.

Standard Delivery Process

Speedy Free Quotation

Get a fast, no-obligation quote tailored to your stone CNC machine needs.

Confirm Order Details

Finalize specifications, payment, and delivery terms with full transparency.

Production Readiness

Your machine enters production immediately with strict quality control.

Transparent Shipping

Real-time logistics tracking ensures safe and timely delivery worldwide.

Custom Delivery Process

Requirement Submission

Share your project details, stone materials, and special cutting requirements.

Quotation and Samples

Receive a customized quotation, with cutting test samples if needed.

Confirm Order Details

Confirm machine configuration, customization options, and production timeline.

Production and Delivery

Your tailor-made machine is manufactured and shipped with reliable global logistics.

GET IN TOUCH

Let's get in touch

Message

Our Contact

Email Address

sally@midecnc.com

Call Us

+8615594977687