4+1 va 5 o‘qli CNC ko‘prik arralari yordamida granit va marmar ish stollarini mukammal kesishga erishing.

Oshxona stol usti har qanday uy ta’mirlash loyihasining yuragi hisoblanadi. Granit, marmar yoki kvarts bilan ishlashingizdan qat’i nazar, toza va aniq kesish yuqori sifatli natijalarga erishish uchun muhimdir. An’anaviy qo‘lda kesish usullari zamonaviy dizayn talablariga javob bera olmaydi, bu esa material isrof bo‘lishiga va notekis qirralarga olib keladi.

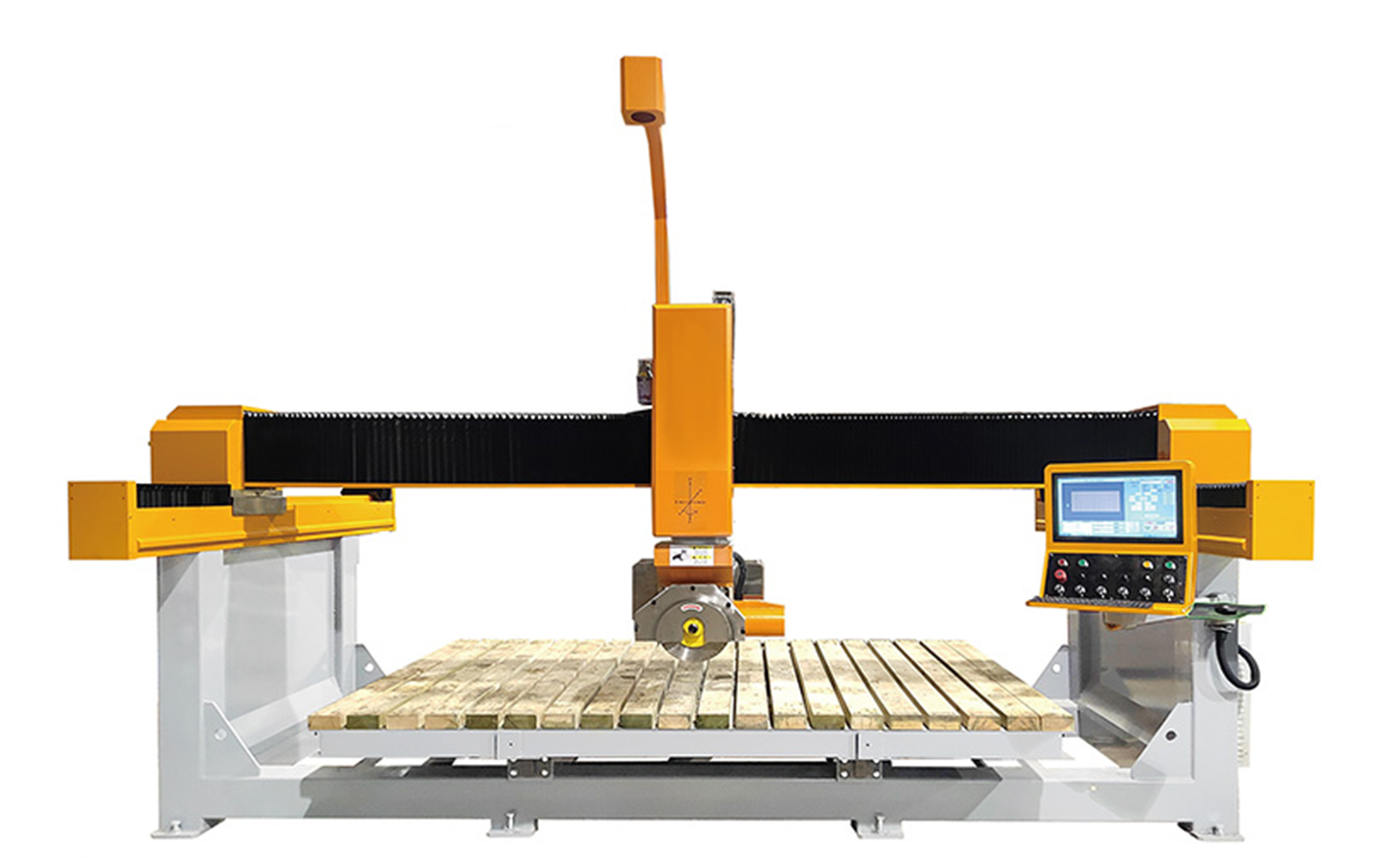

CNC ko‘prik arralari shu yerda muhim ahamiyat kasb etadi — ilg‘or avtomatlashtirish va aniq kesishni birlashtirib, har safar professional sifatli ish stollarini taqdim etadi.

- Tosh ish stollarini tayyorlash va kesish bo‘yicha bosqichma-bosqich ko‘rsatma

- Muhim xavfsizlik omillari

- Eng yaxshi natijalar uchun tavsiya etilgan CNC ko‘prik arralari modellari

Aniqlik bilan kesish

Toza va uzviy qirralar uchun millimetrning kichik qismigacha aniq.

Tezroq ishlab chiqarish

Murakkab shakllar va kran teshiklarini avtomatlashtiring, ishlab chiqarishni tezlashtiring.

Materialni optimallashtirish

Chiqindini kamaytirish va tosh plitalaridan maksimal foydalanish uchun aqlli joylashtirishdan foydalaning.

Ko‘p qirralilik

Bir mashina bilan granit, marmar, kvarts va sinterlangan toshni qayta ishlang.

Tosh ish stollarini kesish uchun bosqichma-bosqich jarayon

O‘lchov va CAD dizayni

Shkaf o‘lchamlari va har qanday qurilma teshiklarini o‘lchang.

CAD dasturlari (AutoCAD yoki Alphacam kabi) yordamida ish stolini loyihalang.

Chiqindilar va qirralar profillari uchun ruxsatlarni qo‘shing.

Maslahat: Har doim o‘lchovlarni ikki marta tekshiring — ikki marta o‘lchang, bir marta kesing.

Material tanlash va tayyorlash

Yoriq va bo‘shliqlarsiz yuqori sifatli tosh plitalarni tanlang.

Plitani rangning birxilligini va tuzilmaning yaxlitligini tekshiring.

Plitani vakuum ko‘taruvchi yoki kran yordamida ehtiyotkorlik bilan mashina stoliga joylashtiring.

CNC ko‘prik arra sozlash

Mashinani kalibrlash (pichoq tezligi, oziqlantirish tezligi, kesish chuqurligi).

CAD dizaynini CNC boshqaruv tizimiga yuklang.

Pichoq yo‘li dasturlangan tartibga mos kelishini tekshiring.

Qattiq kesish

Stol yuzasining bo‘limlarini ajratish uchun katta kesishlardan boshlang.

Moslamaning lazer yo‘riqchisi yoki kamera joylashuv tizimidan tekislash uchun foydalaning.

Aniqlik bilan kesish va chet profilini yaratish

Chuqur yuvinish idishlari, kranlar va pechka ochilishlari uchun batafsil kesishlarni bajaring.

Chekka profillarini shakllantiring — dumaloq, burchak, ogee yoki maxsus uslublar.

Professional maslahat: Midecnc mashinalari 4+1 o‘qli boshqaruv bilan kesish va frezalash o‘rtasida muammosiz almashinish imkonini beradi.

Polishing va yakunlash

Yuzani yaxshilash uchun olmosli polishing padlarini ishlating.

Stol yuzasini namlik va dog‘lardan himoya qilish uchun muhrlang.

Tavsiya etilgan CNC ko‘prik arra modellari

Vanna xonasi mahsulotlarini ishlab chiqarishga moslashtirilgan ideal CNC yechimini tanlang. Midecnc har qanday hajmdagi operatsiyalar uchun ishonchli modellarga ega, bo‘shliq usti ishlov berishdan tortib aniqlik bilan o‘yma ishlargacha.

4 o'qli CNC ko'prik arra

Hammom peshtaxtalari va panellarini qayta ishlash uchun moʻljallangan kuchli va foydalanishga qulay 4 o‘qli CNC ko‘prik arrasi. U burchakli kesish, teshik shakllantirish va plitalarni moslashuvchan boshqarishni ta’minlaydi – professional tosh ishlab chiqaruvchilar uchun ideal tanlov.

- 4-o‘qli kesish moslashuvchanligi: To‘g‘ri, qiya va yumaloq kesimlarni yuqori aniqlikda bajaradi

- Integratsiyalashgan teshik burg‘ulash: Bitta ish jarayonida kran, drenaj yoki rakovina teshiklarini kesish

- Heavy-duty frame & easy control: Built for stability and intuitive operation

5 o‘qli CNC ko‘prik arra

Yuqori darajadagi ichki va arxitektura ishlari uchun mo‘ljallangan 5 o‘qli CNC ko‘prik arrasi o‘ta aniqlikdagi qiyshiq kesish, egri shakllar, rakovina teshiklari va hattoki relyef o‘ymalarni ham bir aqlli jarayonda bajaradi. Sinterlangan tosh, marmar, kvarts va keramika panellari uchun ishlab chiqilgan bu uskuna dizaynerlar va ishlab chiqaruvchilar uchun tengsiz samaradorlik va moslashuvchanlikni taqdim etadi.

- Photo Taking & Suction Cup System: Advanced alignment and stone stabilization system enhances safety and accuracy.

- Haqiqiy 5-o‘qli kesish: To‘liq XYZ harakati, shpindel aylanishi va og‘ish bilan ilg‘or 3D profillash, chekka shakllantirish va 45° gacha egilgan kesimlarni ta'minlaydi.

- Murakkab shakllarni kesish uchun mos: uchburchaklar, ellipslar, romblar, doiralar, peshtaxtalar, stollar va boshqalar uchun ideal.

Bizning mutaxassis savdo jamoamiz bilan bog'laning

Sizga CAD qo‘llab-quvvatlashi bilan bitta boshli tosh burg‘ulash kesgichi yoki hovuz teshigi va stol usti ishlab chiqarish uchun to‘liq CNC tosh mashinasi kerak bo‘lsa ham, biz sizga aniq o‘lchovda kengayishga yordam beramiz.

Tavsiya etilgan o‘qish

Ushbu ekspert qo‘llanmalari bilan CNC tosh mashinalari bo‘yicha bilimlaringizni kengaytiring: