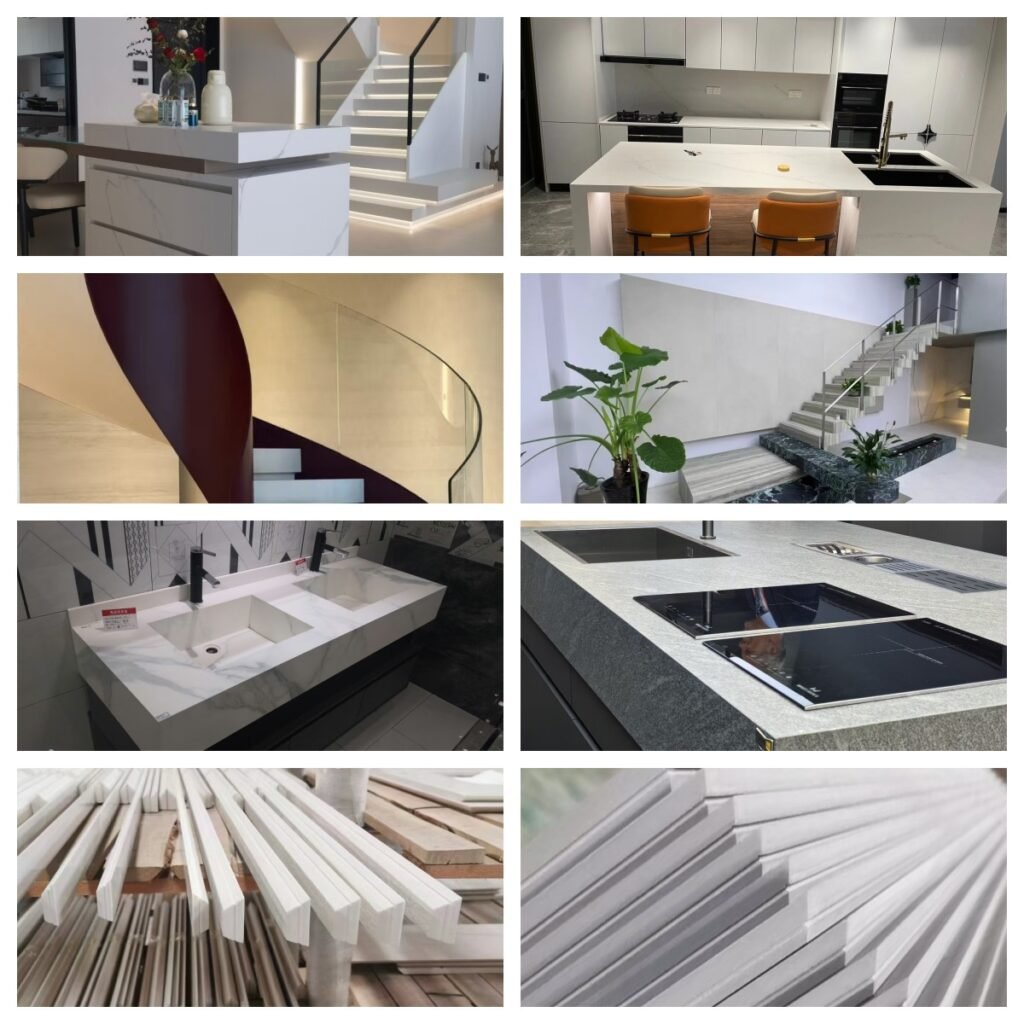

Bridge saws are essential tools in the stone fabrication industry, widely used to cut granite, marble, quartz, and sintered stone for countertops, floors, and decorative pieces. With advanced cutting capabilities and automation features, they greatly improve processing efficiency and product quality.Among the most common models on the market are the 4 Axis , 4+1 Axis , and 5 Axis CNC bridge saws . But how do you choose the right one?At Midecnc , we provide tailored solutions for various processing needs. Below, we break down the key differences, advantages, and use cases for each type of machine.

| Feature | 4 Axis | 4+1 Axis | 5 Axis |

|---|---|---|---|

| Blade Movement | X, Y, Z, A | X, Y, Z, A (+ fixed C) | X, Y, Z, A, C (full motion) |

| C-Axis Control | None | Manual/Indexed | Fully Automatic |

| Suitable for | Straight + angled cuts | Sink cutouts, tapers | Complex 3D shapes, miters |

| Programming | Basic | Intermediate | Advanced |

| Price | Entry-level, most affordable | Mid-range, balanced cost and value | High-end, premium investment |

| Automation Level | Moderate | High | Full |

4 Axis CNC Stone Cutting and Edge Polishing Machine

Ideal for: Straight cutting, chamfering, and simple shape profiling

- X, Y, Z, and one rotational axis

- Suitable for countertop cutting and regular shapes

- Equipped with infrared positioning and optional camera vision

- Excellent cost-performance balance

4+1 Axis CNC Bridge Saw

Ideal for: Customers who need more flexibility but want to control costs

- Adds an extra rotation or spindle axis to the 4-axis base

- Can switch between saw blade and spindle automatically

- Supports engraving and advanced detailing

- More efficient than pure 4-axis but more affordable than 5-axis

5 Axis CNC Bridge Saw

Ideal for: Complex 3D cutting, advanced fabrication, and full-angle operations

- X, Y, Z + dual rotation axes for full 5-axis interpolation

- Performs miter cuts, curved surfaces, undercut sink holes, and sculpting

- Combines blade cutting with CNC milling

- Top-tier solution for custom stone processing factories

Talk to Our Expert Sales Team

Whether you need a single-head rock drilling cutter with CAD support or a complete CNC stone machine for basin hole and countertop fabrication, we’re here to help you scale with precision.

Recommended Reading

Expand your knowledge about CNC stone machinery with these expert guides: