Logre resultados impecables en el corte de encimeras de granito y mármol con sierras puente CNC de 4+1 y 5 ejes.

La encimera de la cocina es el corazón de cualquier proyecto de renovación. Ya sea que trabaje con granito, mármol o cuarzo, lograr cortes limpios y precisos es esencial para obtener resultados de alta gama. Los métodos tradicionales de corte manual a menudo no cumplen con las demandas del diseño moderno, lo que provoca desperdicio de material y bordes desiguales.

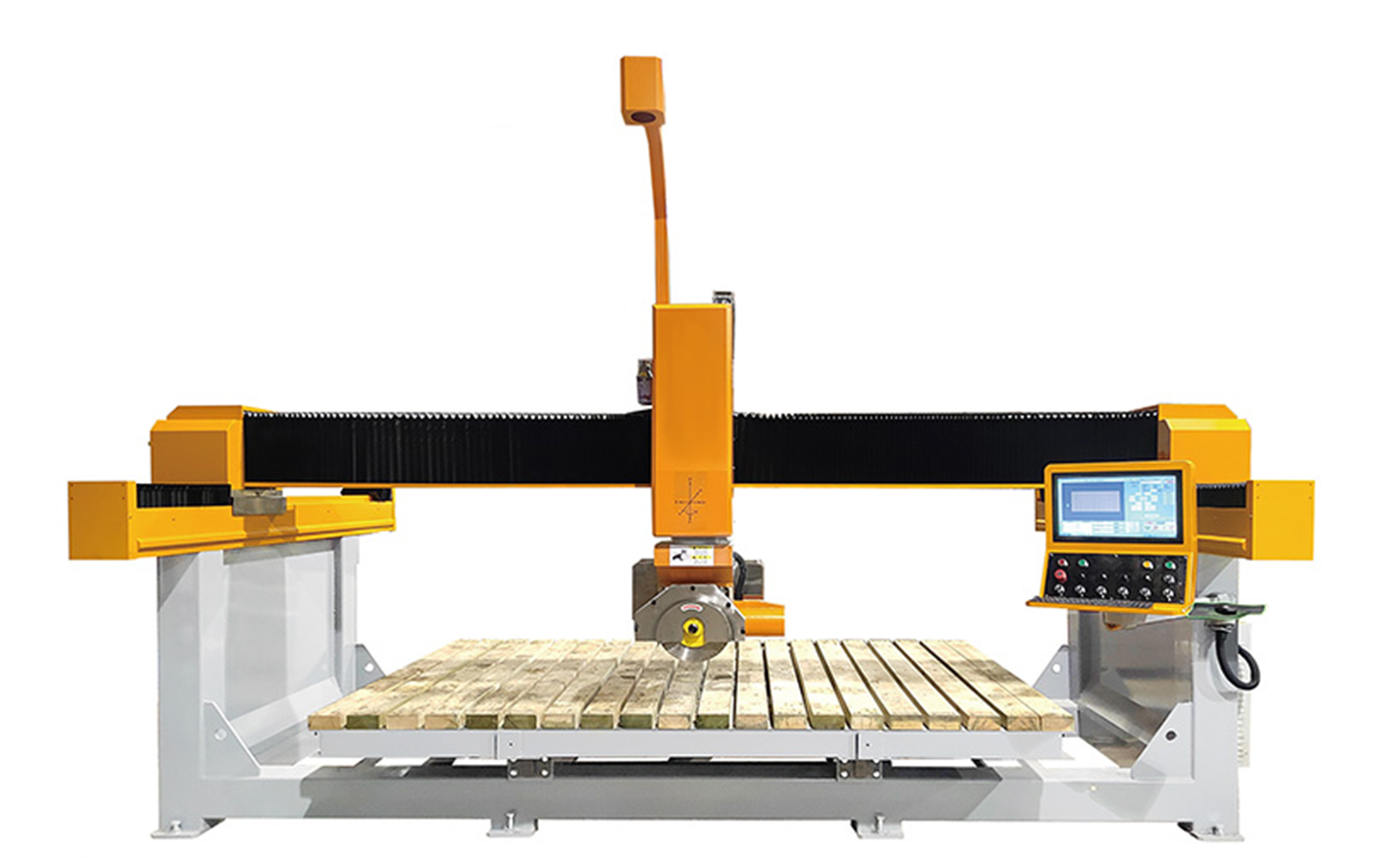

Aquí es donde entran en juego las sierras puente CNC, que combinan automatización avanzada con corte de precisión para ofrecer encimeras de calidad profesional en todo momento.

- Cómo preparar y cortar encimeras de piedra paso a paso

- Consideraciones clave de seguridad

- Modelos recomendados de sierras puente CNC para obtener los mejores resultados

Cortes de precisión

Precisión dentro de fracciones de milímetro para bordes limpios y sin costuras.

Producción más rápida

Automatice formas complejas y recortes para fregaderos para acelerar la fabricación.

Optimización de materiales

Use anidación inteligente para reducir el desperdicio y maximizar el uso de las losas.

Versatilidad

Procese granito, mármol, cuarzo y piedra sinterizada con una sola máquina.

Proceso paso a paso para cortar encimeras de piedra

Medición y diseño CAD

Mida las dimensiones del gabinete y los recortes para los electrodomésticos.

Diseñe la encimera utilizando software CAD (como AutoCAD o Alphacam).

Incluya tolerancias para voladizos y perfiles de borde.

Consejo: Siempre verifique las medidas — Mida dos veces, corte una vez.

Selección y preparación de materiales

Elija losas de piedra de alta calidad sin grietas ni huecos.

Inspeccione la losa para verificar la consistencia del color y la integridad estructural.

Cargue la losa cuidadosamente sobre la mesa de la máquina usando un elevador de vacío o una grúa.

Configuración de sierra puente CNC

Calibre la máquina (velocidad de la hoja, velocidad de avance, profundidad de corte).

Cargue su diseño CAD en el sistema de control CNC.

Verifique que la trayectoria de la hoja coincida con el diseño programado.

Corte en bruto

Comience con cortes más grandes para separar secciones de la encimera.

Utilice la guía láser o el sistema de posicionamiento por cámara de la máquina para la alineación.

Corte de precisión y perfilado de bordes

Realice cortes detallados para fregaderos, grifos y aberturas de estufa.

Modele los perfiles de borde—borde redondeado, bisel, ogee o estilos personalizados.

Consejo profesional: Las máquinas Midecnc permiten cambiar sin problemas entre corte y fresado con control de 4+1 ejes.

Pulido y Acabado

Use almohadillas de pulido de diamante para refinar la superficie.

Selle la encimera para protegerla contra la humedad y las manchas.

Modelos recomendados de sierras puente CNC

Elija la solución CNC ideal adaptada a la fabricación de productos para baños. Desde el procesamiento de encimeras hasta el grabado de precisión, Midecnc ofrece modelos fiables para todo tipo de operaciones.

Sierra puente CNC de 4 ejes

Una sierra puente CNC potente y fácil de usar, diseñada especialmente para el procesamiento de encimeras y paneles de baño. La configuración de 4 ejes permite cortes a inglete, perforación de orificios y manejo flexible de losas, ideal para talleres profesionales de piedra.

- Flexibilidad de corte de 4 ejes: permite cortes rectos, en bisel y circulares con alta precisión

- Perforación integrada: Realiza el corte de orificios para grifos, desagües o fregaderos en un solo flujo de trabajo

- Heavy-duty frame & easy control: Built for stability and intuitive operation

Sierra de puente CNC de 5 ejes

Diseñada para aplicaciones interiores y arquitectónicas de alto nivel, la sierra puente CNC de 5 ejes permite cortes en inglete ultra precisos, modelado de curvas, recortes para fregaderos e incluso relieves esculpidos, todo en un flujo de trabajo inteligente. Diseñada para piedra sinterizada, mármol, cuarzo y paneles cerámicos, ofrece una eficiencia y versatilidad inigualables para diseñadores y fabricantes.

- Photo Taking & Suction Cup System: Advanced alignment and stone stabilization system enhances safety and accuracy.

- Corte real de 5 ejes: Movimiento completo en XYZ con rotación e inclinación del husillo para perfilado 3D avanzado, conformado de bordes y cortes en bisel (hasta 45°).

- Maneja formas complejas: Ideal para cortar triángulos, elipses, rombos, círculos, encimeras, mesas y más.

Hable con nuestro equipo experto de ventas

Ya sea que necesite un cortador de perforación de roca de un solo cabezal con soporte CAD o una máquina CNC completa para la fabricación de agujeros para lavabos y encimeras, estamos aquí para ayudarle a escalar con precisión.

Lectura recomendada

Amplíe su conocimiento sobre maquinaria CNC para piedra con estas guías de expertos: